Operation manual

Ⅰ

3

−

3

3.3 When a mark recognition error occurs

Error screen

Causes of the error

①

Stained BOC mark

②

A BOC mark is not within the

inspection frame.

③

Input error of BOC mark coordinate

data

* An area fiducial mark causes the

similar error.

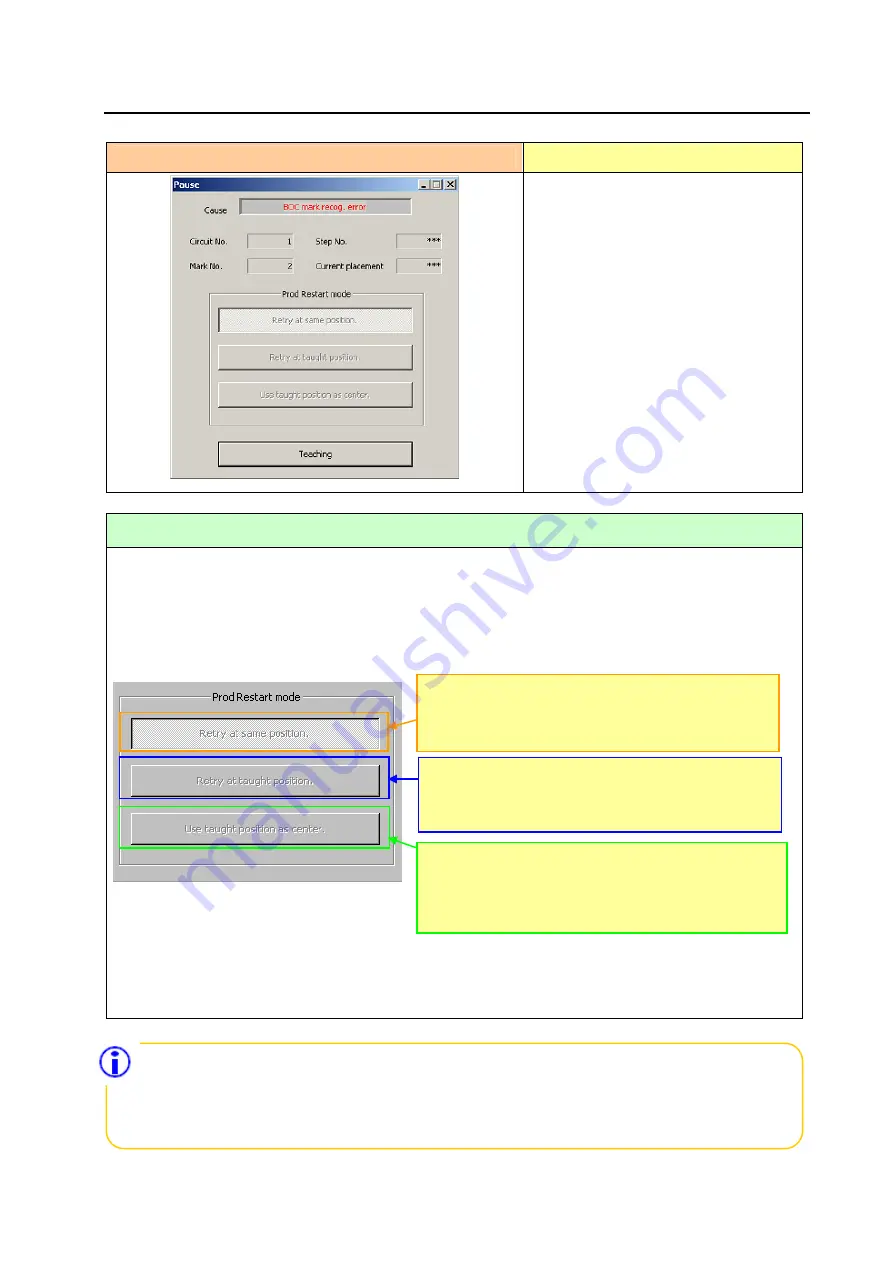

How to handle an error

1) Select [CAMERA] on the operating screen or the HOD and perform teaching for the center of the

mark.

2) If you perform a teaching operation, you can select the “Prod Restart mode.”

Judge the mark condition (its shape and whether it is stained or not) and check to see the mark is

located within the inspection frame, and then select the desired button.

3) Specify the “Prod Restart mode,” and press the <START> switch. The system processes the mark

according to the “Prod Restart mode” you specified.

Selection of the “Prod Restart mode” is effective for only a board that is currently

centered.

Therefore, a value of the production program is applied to the next board.

If the conditions of all marks on boards of the current lot change due to lot change, edit

the production program.

Recognizes (retries) a mark again.

Select this button when the mark is

“within the

inspection frame,” and “the mark shape is normal.”

Recognizes a mark at the taught position again.

Select this button when the mark is

“not within the

inspection frame,” and “the mark shape is normal.”

Omits the mark recognition operation, and forcibly

processes the taught position as the coordinates of the

mark.

Select this button when

“the mark shape is abnormal.”