RXB PLUS ROTARY SCREW COMPRESSOR UNITS

INSTALLATION

070.101-IOM (JAN 13)

Page 8

PARALLEL ALIGNMENT

6.

To.check.parallel.alignment,.as.shown.in.Figure.7,.reposi-

tion.dial.indicator.so.the.stem.is.in.contact.with.the.rim.of.the.

compressor.hub,.as.shown.in.Figure.8.

Check.the.dial.indicator.to.be.sure.that.the.indicator.stem.is.

slightly.loaded.so.as.to.allow.movement.in.both.directions.

7.

Check.parallel.height.misalignment.by.setting.dial.indica-

tor.at.zero.when.viewed.at.the.12.o’clock.position..Rotate.

both.coupling.hubs.together.180

O

.(6.o’clock.position)..At.this.

position.the.dial.indicator.will.show.TWICE.the.amount.of.

parallel.height.misalignment...

8.

Loosen.motor.anchor.bolts.and.add.or.remove.shims.under.

the.four.motor.feet.until.parallel.height.misalignment.is.within.

specified.tolerance.when.anchor.bolts.are.retightened.

CARE MUST BE USED WHEN COR-

RECTING FOR PARALLEL MIS-

ALIGNMENT TO ENSURE THAT

THE AXIAL SPACING AND ANGULAR MISALIGNMENT

IS NOT SIGNIFICANTLY DISTURBED.

9.

After.the.parallel.height.misalignment.is.within.tolerance,.

repeat.Steps.1.through.5.until.angular.misalignment.is.within.

specified.tolerance.................

..........

10.

Check.parallel.lateral.misalignment.by.positioning.dial.

indicator.so.the.stem.is.in.contact.with.the.rim.of.the.com-

pressor.hub.at.3.o’clock,.as.shown.in.Figure.9.

Set.indicator.at.zero.and.rotate.both.coupling.hubs.together.

180

O

.(9.o’clock.position),.as.shown.in.Figure.8.

Adjust.parallel.lateral.misalignment.using.the.motor.adjusting.

screws.until.reading.is.within.specified.tolerance.

11.

. Recheck. angular. misalignment. and. realign. if. neces-

sary.

12.

Tighten.motor.anchor.bolts.and.rotate.both.coupling.hubs.

together,. checking. the. angular. and. parallel. misalignment.

through.the.full.360

O

.travel.at.90

O

.increments..If.dial.readings.

are.in.excess.of.specified.tolerance,.realign.as.required.

13.

.When. the. coupling. hubs. have. been. aligned. to. within.

specified.tolerance,.a.recording.of.the.cold.alignment.must.

be.made.for.unit.records.and.usage.during.hot.alignment.

14.

Bump.the.motor.to.check.for.correct.compressor.rotation..

COMPRESSOR ROTATION IS CLOCKWISE WHEN FAC-

ING COMPRESSOR SHAFT (see “CHECKING MOTOR/

COMPRESSOR ROTATION”, page 9).

After. verification,.

install.gear.or.disk.drive.spacer,.as.applicable.

15.

.Install.the.coupling.guard.before.operating.the.compres-

sor.

When installing drive spacer, make

sure that hub spacing is within

limits shown on the Coupling Data

Table applicable to the coupling being installed and that

the clamping bolt(s) are properly torqued.

Figure 7 - Parallel Misalignment

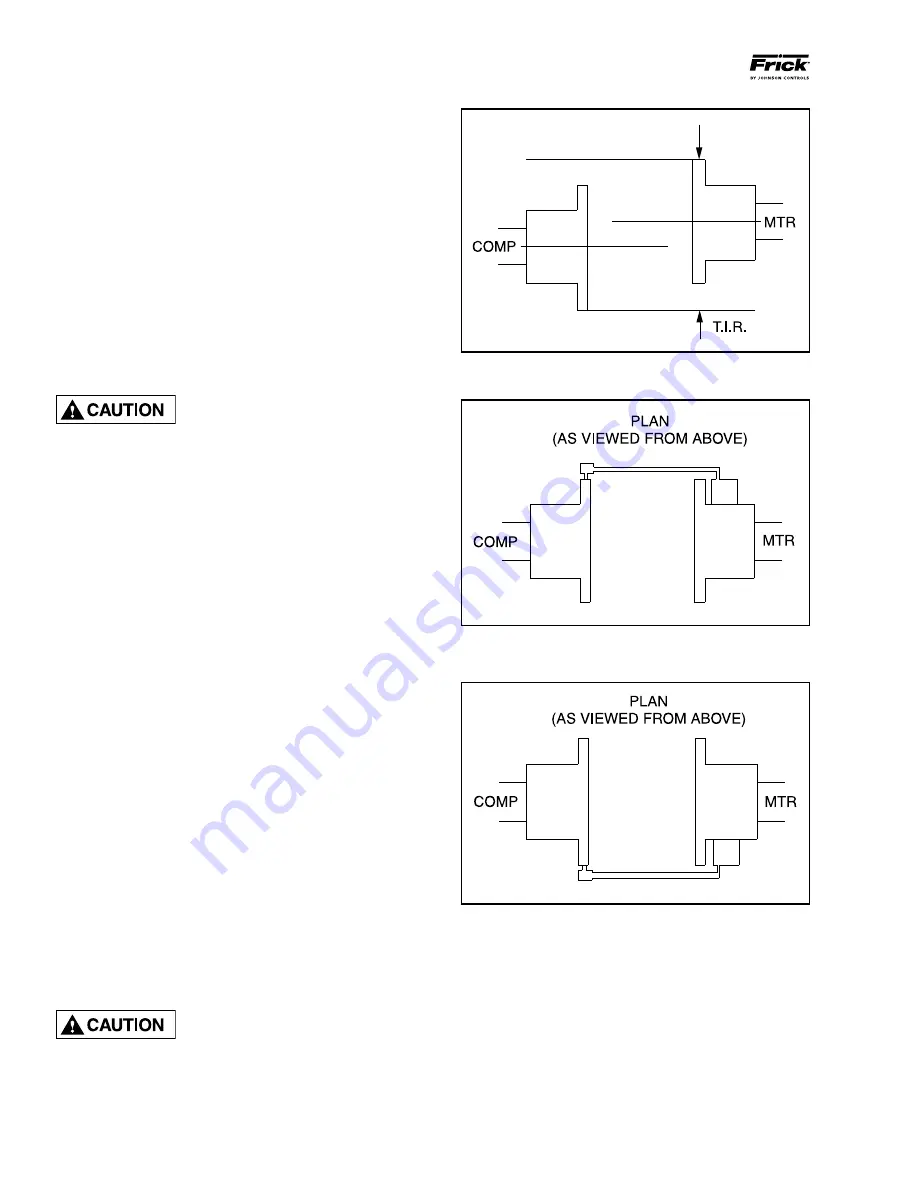

Figure 8 - Dial Indicator Attached (At 9 O’clock)

Figure 9 - Dial Indicator At 3 O’clock