RXB PLUS ROTARY SCREW COMPRESSOR UNITS

INSTALLATION

070.101-IOM (JAN 13)

Page 12

1.

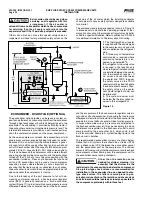

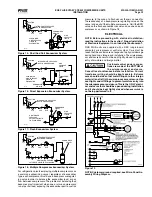

The.thermosyphon.oil.cooler.

is.supplied.with.the.oil.side.piped.

to.the.compressor.unit.and.stub.

ends.supplied.on.the.refrigerant.

side.

2.

. A. three-way. oil. temperature.

control. valve. is. required. where.

condensing. temperature. is. ex-

pected.to.go.below.65

O

F.

3.

A.refrigerant-side.safety.valve.

is. required. in. this. location. only.

when.refrigerant.isolation.valves.

are.installed.between.the.cooler.

and. thermosyphon. receiver.. If.

no. valves. are. used. between.

the. cooler. and.TSOC. receiver,.

the. safety. valve. on. the.TSOC.

receiver.must.be.sized.to.handle.

the.volume.of.both.vessels..Then,.

the. safety. valve. on. the. cooler.

vent.(liquid.refrigerant.side).can.

be.eliminated.

4.

The. system. receiver. must.

be.below.the.thermosyphon.re-

ceiver.in.this.arrangement.

Figure 14

Extra caution should be used when

servicing an oil separator with this

arrangement. If the oil cooler is

valved off from an oil separator which has been evacuated

for servicing, then the oil cooler could relieve into the

separator vessel if the 75 psi delta p setpoint is exceeded.

Other.units,.which.do.not.use.this.special.safety.valve.ar-

rangement,.will.have.factory.mounted.safety.valves.on.the.

shell. side. of. the. oil. cooler. which. the. installing. contractor.

should.pipe.into.house.safety.systems.designated.suitable.

for.oil.relief.

The.component.and.piping.arrangement.shown.in.Figure.14.

is.intended.only.to.illustrate.the.operating.principles.of.ther-

mosyphon.oil.cooling..Other.component.layouts.may.be.better.

suited.to.a.specific.installation..Refer.to.publication.070-900E.

for.additional.information.on.Thermosyphon.Oil.Cooling.

ECONOMIZER - HIGH STAGE (OPTIONAL)

The.economizer.option.provides.an.increase.in.system.ca-

pacity.and.efficiency.by.subcooling.liquid.from.the.condenser..

through.a.heat.exchanger.or.flash.tank.before.it.goes.to.the.

evapora.tor..The.subcooling.is.provided.by.flashing.liquid.in.

the.economizer.cooler.to.an.intermediate.pressure.level.The.

intermediate.pressure.is.provided.by.a.port.located.part.way.

down.the.compres.sion.process.on.the.screw.compressor.

As.the.screw.compressor.unloads,.the.economizer.port.will.

drop.in.pressure.level,.eventually.being.fully.open.to.suction..

Because.of.this,.an.output.from.the.microproces.sor.is.gener-

ally.used.to.turn.off.the.supply.of.flashing.liquid.on.a.shell.and.

coil.or.DX.economizer.when.the.capacity.falls.below.approxi-

mately.45%-60%.capacity.(85%-90%.slide.valve.position)..

This.is.done.because.the.compressor.will.be.more.efficient.

operating.at.a.higher.slide.valve.position.with.the.economizer.

turned.off,.than.it.will.at.a.low.slide.valve.position.with.the.

economizer.turned.on..Please.note.however.that.shell.and.

coil.and.DX.economizers.can.be.used.at.low.compressor.

capaciti.es.in.cases.where.efficien.cy.is.not.as.important.as.

ensuring.that.the.liquid.supply.is.subcooled..In.such.cases,.

the.economi.zer.liquid.solenoid.can.be.programmed.to.be.left.

open.whenever.the.com.pressor.is.running.

Due. to. the. tendency. of. the. port. pressure. to. fall. with. de-

creasing. compressor. capacity,. a. back-pressure. regulator.

valve. (BPR). is. generally. required. on. a. flash. economizer.

system.(Figure.17).in.order.to.maintain.some.preset.pressure.

dif.ference.between.the.subcooled.liquid.in.the.flash.vessel.

and.the.evaporato.rs..If.the.back-pressure.regulator.valve.is.

not.used.on.a.flash.economizer,.it.is.possible.that.no.pressure.

difference.will.exist.to.drive.liquid.from.the.flash.vessel.to.the.

evaporators,.since.the.flash.vessel.will.be.at.suction.pressure..

In.cases.where.wide.swings.in.pressure.are.anticipated.in.

the.flash.econo.mizer.vessel,.it.may.be.necessary.to.add.an.

outlet.pressure.regulator.to.the.flash.vessel.outlet.to.avoid.

overpressurizing. the. economizer. port,. which. could. result.

in.motor.overload..Example:.A.system.feeding.liquid.to.the.

flash.vessel.in.batches.

The.recommended.economizer.systems.are.shown.below..

Notice.that.in.all.systems.there.should.be.a.strainer.(STR).

and.a.check.valve.(VCK).between.the.economizer.vessel.

and.the.economizer.port.on.the.compressor..The.strainer.

prevents.dirt.from.passing.into.the.compressor.and.the.check.

valve.prevents.oil.from.flowing.from.the.compressor.unit.to.

the.econo.mizer.vessel.during.shutdown.

Other than the isolation valve

needed for strainer cleaning, it is

essential that the strainer be the

last device in the economizer line before the compres sor.

Also, piston-type check valves are recom mended for

installation in the economizer line, as opposed to disc-

type check valves. The latter are more prone to gas-

pulsation-induced failure. The isolation and check val ves

and strainer should be located as closely as possible to

the compressor, preferably within three feet.