RXB PLUS ROTARY SCREW COMPRESSOR UNITS

MAINTENANCE

070.101-IOM (JAN 13)

Page 56

11

01

31

21

11

1

19

29

7

30

29

30

20

22

21

23

24

28

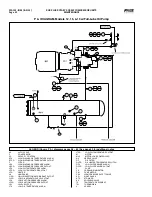

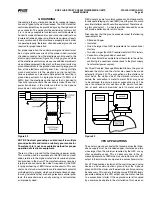

REMOTE LOAD

REMOTE START/RUN/STOP

38

39

5

37

36

35

34

33

REMOTE UNLOAD

(N.O. HELD CLOSED)

1 LSL

COMPR. AUX

32

30

OIL PUMP AUX

29

28

27

26

*

FROM LN.15

(OOX)

B

19

*

25

24

23

22

20

1

18

17

FU1

20

2

22

3

FU2

19

FU3

21

FU5

24

4

26

5

FU4

23

25

28

6

27

FU6

REMOTE UNLOAD

LIQUID INJECTION

PRESSURE REGULATOR

(ONLY ON BOOSTERS

WITH LIQ INJ)

REMOTE LOAD

REMOTE START/RUN/STOP

OIL LEVEL

(NOT REQUIRED WITH

FULL-LUBE OIL PUMP)

1

2

2

4

1

3

6

3

8

4

5

7

2

COMPRESSOR AUX

OIL PUMP AUX

AUX 1 (SEE NOTE B)

AUX 2 (SEE NOTE B)

COMPR. RUN TIME METER

COMPR. START/RUN

60

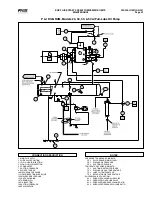

DECREASE TO 2.2 Vi

LIQUID INJECTION (IF REQ'D)

HI VI LIQ INJ (IF REQ'D)

ECONOMIZER (IF REQ'D)

ALARM (PRE & CUTOUT)

RELAY &/OR LAMP OPTIONAL

DECREASE TO 3.5 Vi

SLIDE VALVE LOAD

SHOWN W/SOL ON COMPR

<a> COIL W/SOL ON BASE

SLIDE VALVE UNLOAD

SHOWN W/SOL ON COMPR

<b> COIL W/SOL ON BASE

5

10

12

6

9

11

14

7

16

8

13

15

12

13

14

15

16

17

38

CR

SEE

NOTE C

2

<a>COIL

<b>COIL

FOR DIGITAL I/O

CUSTOMER SUPPLIED 120 VAC CONTROL TRANSFORMER POWER SOURCE IS REQUIRED

ALL POWER SOURCES SHALL BE GROUNDED ON ONE SIDE

-ISOLATED AND SEPARATED FROM OTHER INDUCTIVE LOADS SUCH AS LIGHTING CIRCUITS

-OR FROM FRICK SUPPLIED OR SPECIFIED STARTER, USE MINIMUM #12 AWG FOR FEED

IF SEPARATE FEED FOR HEATER CIRCUIT IS DESIRED,

REMOVE JUMPERS 1 TO 1A & 2 TO 2A & CONNECT

A SEPARATE 120 VAC SOURCE TO 1A & 2A

12

18

17

16

15

14

13

FU10

32

8

FU7

FU8

31

10

34

9

36

FU9

33

35

12

11

38

40

FU11

B

37

39

13

42

41

FU12

FU13

10

09

#14 RED

2 FU

07

10

08

5

06

15

14

44

46

FU14

43

FU15

45

16

SBC TERMINALS

48

FU16

47

6

STOP

EMERGENCY

05

04

03

02

1A FU

1 FU

15

1A

15

25A

25

1

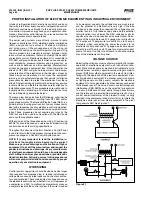

PROGRAMMABLE CONTROL

DATA CODE BIT 3

OIL PUMP START/RUN

63

OIL HEATER

3, 4

ALL NEUTRAL (EXP: 2 & 2A)

WIRING TO BE WHITE

EXCEPT WHERE NOTED

ALL HEATER WIRING

TO BE #14 AWG

SEPARATOR OIL HEATER(S)

5 KW HTR'S

1 KW HTR'S OPTIONAL

PROGRAMMABLE CONTROL

DATA CODE BIT 2

PROGRAMMABLE CONTROL

DATA CODE BIT 1

PROGRAMMABLE CONTROL

DATA CODE BIT 0

SPARE

33

10

7

39

35

9

34

*

CR

CR

3

*

32

31

OIL PUMP

HAND

AUTO

(XOO)

(OOX)

TO LN. 30

OFF

*

39

26

27

2A

2

NEUTRAL

HOT

1CR

1CR

HOT

ADD 1A FU FOR 115V-1KW HTR

FOR (2) 115V-1 KW HTR'S,MOVE

WIRE TO 1A FU & NUMBER 25A

NEUTRAL

GROUND BAR IN MICRO

EARTH BUSBAR AT

POWER SOURCE

TIE NEUTRAL TO GROUND

AT SOURCE

ALL NEUTRALS ENTERING

THIS ENCLOSURE SHALL

BE TIED TOGETHER AT

SOURCE, NOT IN THIS

ENCLOSURE

HEATER

HEATER

RXBELD1

MICRO PANEL ASSEMBLY WIRING DIAGRAM