RXB PLUS ROTARY SCREW COMPRESSOR UNITS

MAINTENANCE

070.101-IOM (JAN 13)

Page 38

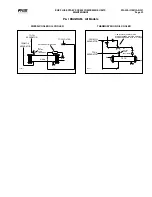

4.

.Close.the.service.valve.located.between.the.compressor.

and.the.liquid.injection,.thermal.expansion.valve.

5.

.Carefully.loosen.the.capscrews.securing.the.strainer.cover.

to.the.strainer...Allow.pressure.to.relieve.slowly.

6.

.When.all.entrapped.refrigerant.has.been.relieved,.care-

fully.remove.the.loosened.capscrews.(as.liquid.refrigerant.

is. some.times. caught. in. the. strainer),. strain.er. cover,. and.

strainer.basket.

7.

.Wash.the.strainer.basket.and.cover.in.sol.vent.and.blow.

them.clean.with.air.

8.

.Reassemble.the.strainer.

9.

. Open. the. service. valve. between. the. compressor. and.

the.liquid.injection.thermal.expansion.valve.and.check.for.

leakage.

10.

.Screw.out.the.manual.solenoid.valve.stem.

11.

.Carefully.open.the.liquid.supply.service.valve.

12.

.Leak.test.

13.

.Open.suction.and.discharge.valves.and.readjust.suc-

tion.check.valve.bypass.(if.required)..Close.the.disconnect.

switches. for. the. compressor. and. (if. applicable). oil. pump.

motor.starters.

14.

.Start.the.unit.

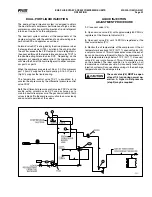

COALESCER FILTER ELEMENT

When. changing. the. coalescer. filter. element,. it. is. recom-

mended.that.the.oil.and.oil.filter(s).be.changed..Applicable.

strainer.elements.should.be.removed.and.cleaned.

1.

.Refer.to.

CHANGING OIL,

.Steps.1.thru.8.

2.

.Remove.coalescer.head.and.gasket..Discard.the.gasket.

3.

.Remove.and.retain.the.nut.securing.the.coalescer.filter.

retainer.

4.

. Remove. the. retainer,. coalescer. filter. element,. and. 2.

O-rings...Discard.the.filter.element.

5.

.Install.the.new.coalescer.filter.element.

Seat the element in center of locat-

ing tabs on separator bulkhead.

6.

. Replace. the. coalescer. filter. retainer. and. nut..

DO NOT

OVERTIGHTEN THE NUT.

Torque. values. for. nut. are:. 15.

ft-lb.for.models.12.and.15;.17.ft-lb.for.19.and.24;.and.21.ft-lb.

for.30–50..Install.jam.nut.

7.

.Install.new.head.gasket.and.replace.the.coalescer.head.

8.

.Tighten.the.head.bolts...

NOTE: WHEN THE COM PRES-

SOR UNIT IS REPRESSURIZED, RE TIGHTEN THE HEAD

BOLTS TO PREVENT THEM FROM LOOSENING.

9.

.Refer.to.

CHANGING OIL,

.Steps.9.thru.14.

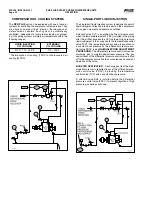

CHANGING OIL

DO NOT MIX OILS of different

brands, manufacturers, or types.

Mixing of oils may cause excessive

oil foaming, nuisance oil level cutouts, oil pressure loss,

gas or oil leakage and catastrophic compressor failure.

Shut.down.the.unit.when.changing.oil...At.the.same.time,.

all.oil.filter.cartridges.must.be.changed.and.all.oil.strainer.

elements.removed.and.cleaned..The.procedure.is.as.follows:

1.

.Push.

[STOP]

.key.to.shut..down.the.unit.

2.

. Open. the. disconnect. switch. for. the. compressor. motor.

starter.and.(if.applicable).oil.pump.motor.starter..

3.

. Close. the. discharge,. and. liquid. injec.tion. (if. applicable).

service.valves.

4.

.

SLOWLY

.vent.the.separator.to.low-side.system.pres.sure.

using.the.suction.check.valve.bypass..Close.suction.valve.

and.suction.check.valve.bypass...

NOTE: Recover or transfer

all refrigerant vapor in accordance with local ordinances

before opening to atmosphere.

The.separator.

MUST

.be.

equalized.to.atmospheric.pressure..

Oil-entrained refrigerant may vapor-

ize, causing a separator pressure

increase. Repeat venting and re-

covery procedure if neces sary.

5.

.Open.the.drain.valve(s).located.on.the.underside.of.the.

separator.and.drain.the.oil.

6.

.Drain.the.oil.filter,.strainers,.and.oil.cooler,.if.applicable.

7.

.Remove.and.install.new.oil.filter.cartridge(s)..Inspect.check.

valve.in.the.bottom.of.the.filter.housing.to.ensure.that.the.

parts.are.in.good.condition.

8.

.Remove,.clean,.and.reinstall.strainer.ele.ments.in.strainers.

9.

.Evacuate.the.unit.to.29.88".Hg.(1000.microns).

10.

.Open.the.suction.service.valve.and.pressurize.the.unit.

to. system. suction. pressure.. Close. the. suction. valve. and.

leak.test.

11.

.Add.oil.by.attaching.suitable.pressure-type.hose.to.the.

oil-charging.valve.located.on.top.of.the.separator..Using.a.

pressure-type.oil.pump.and.recommended.Frick.oil,.open.

the.charging.valve.and.fill.separator.until.oil.level.is.midway.

in.the.top.sight.glass..The.following.table.gives.approximate.

oil.charge.quantities.

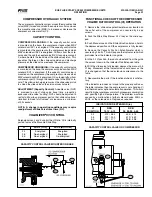

TABLE BASIC OIL CHARGE

RXB MODEL

BASIC CHARGE*(Gal.)

12.&.15

10

19.&.24

14

30.&.39

17

50

21

*.Add.oil.volume.for.external.oil.cooler,.according.to.cooler.

size.selected:.6.x.5.TSOC.-.4.gal.;.6.x.5.WCOC.-.5.gal.;.8.x.

5.TSOC.-.6-1/2.gal.;.and.8.x.5.WCOC.-.8.gal.

12.

.Open.the.suction,.discharge,.and.liquid.injec.tion.service.

valves..Readjust.suction.check.valve.bypass.

13.

.Close.the.disconnect.switch.for.the.compressor.motor.

starter.and.(if.applicable).oil.pump.motor.starter.

14.

.Start.the.unit.