RXB PLUS ROTARY SCREW COMPRESSOR UNITS

INSTALLATION

070.101-IOM (JAN 13)

Page 7

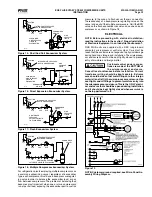

Figure 4 - Angular Misalignment

COUPLING ALIGNMENT PROCEDURE

The.life.of.the.compressor.shaft.seal.and.bearings,.as.well.

as.the.life.of.the.motor.bearings,.is.dependent.upon.proper.

coupling.alignment..Couplings.may.be.aligned.at.the.factory.

but. realignment.

MUST ALWAYS

. be. done. on. the. job. site.

after.the.unit.is.securely.mounted.on.its.founda.tion..Initial.

alignment. must. be. made. prior. to. start-up. and. rechecked.

after.a.few.hours.of.operation..Final.(HOT).field.alignment.

can.only.be.made.when.the.unit.is.at.operating.tempera.ture...

After.final.(HOT).alignment.has.been.made.and.found.to.be.

satisfac.tory.for.approximately.one.week,.the.motor.may.be.

dowelled.to.maintain.align.ment.

NOTE: Frick recommends cold aligning the motor .005”

high. This cold misalignment compensates for thermal

growth when the unit is at operating temperature.

Use.dial.indicators.to.measu.re.the.angular.and.parallel.shaft.

misalign.ment..Coupling.alignment.is.attained.by.alternately.

measuring. angular. and. parallel. misalignment. and. reposi-

tioning.the.motor.until.the.misalignment.is.within.specified.

tolerances..The.following.procedure.is.recommended.

MISALIGNMENT MUST NOT EX-

CEED .004” FOR ALL CH COU-

PLINGS.

ANGULAR ALIGNMENT

1.

.To.check.angular.alignment,.as.shown.in.Figure.4,.attach.

dial.indicator.rigidly.to.the.motor.hub..Move.indicator.stem.

so.it.is.in.contact.with.the.outside.face.of.compressor.hub,.

as.shown.in.Figure.5.

2.

.Rotate.both.coupling.hubs.several.revolutions.until.they.

seek.their.normal.axial.positions.

Check.the.dial.indicator.to.be.sure.that.the.indicator.stem.is.

slightly.loaded.so.as.to.allow.movement.in.both.direc.tions.

3.

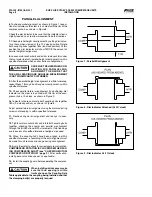

.Set.the.dial.indicator.at.zero.when.viewed.at.the.12.o’clock.

position,.as.shown.in.Figure.5.

4.

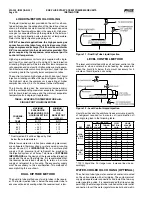

.Rotate.both.coupling.hubs.together.180

O

.(6.o’clock.posi-

tion),.as.shown.in.Figure.6..At.this.position.the.dial.indicator.

will.show.TOTAL.angular.misalignment.

NOTE: The use of a mirror is helpful in reading the indi-

cator dial as coupling hubs are rotated.

5.

.Loosen.motor.anchor.bolts.and.move.or.shim.motor.to.

correct.the.angular.misalignment..

After.adjustments.have.been.made.for.angular.mis.align.ment.

retighten.anchor.bolts.to.prevent.inac.curate.read.ings..Repeat.

Steps.3.through.5.to.check.corrections..Further.adjustments.

and.checks.shall.be.made.for.angular.misalignment.until.the.

total.in.dicator.reading.is.within.the.specified.tolerance.

Figure 5 - Dial Indicator Attached (At 12 O’clock)

Figure 6 - Dial Indicator At 6 O’clock