RXB PLUS ROTARY SCREW COMPRESSOR UNITS

MAINTENANCE

070.101-IOM (JAN 13)

Page 36

MAINTENANCE

3.

Open.suction,.discharge,.and.liquid.injection.service.valves.

and.remove.tags..

4.. Compressor. unit. is. ready. for. prestart. checks.. Refer. to.

PRESTART CHECKLIST.

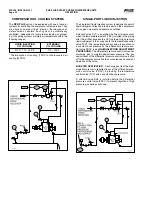

GENERAL INSTRUCTIONS FOR REPLACING

COMPRESSOR UNIT COMPONENTS

When.replacing.or.repairing.components.which.are.exposed.

to.refrigerant,.proceed.as.follows:

1.

.Push

[STOP]

.key.to.shutdown.the.unit.

2.

.Open.disconnect.switches.for.the.compressor.motor.starter.

and.the.oil.pump.motor.starter.(if.applicable).

3.

Close.discharge.service.valve.

4.

.SLOWLY.vent.the.component.to.low-side.system.pressure.

using.suction.check.valve.bypass..Then.close.suction.service.

valve.and.suction.bypass.valve...

NOTE: Recover or transfer

all refrigerant vapor, in accordance with local ordinances,

before opening to atmosphere. The component MUST

be equalized to atmospheric pressure before opening.

Oil-entrained refrigerant may vapor-

ize, causing a pressure increase.

Repeat venting and recovery pro-

cedure, if necessary.

5.

Make.replacement.or.repair.

6.

Isolate.the.low.pressure.transducer,.PE-4,.to.prevent.dam-

age.during.pressurization.and.leak.test.

7.

.Pressurize.the.unit.and.leak.test.

8.

.Evacuate.the.unit.to.29.88".Hg.(1000.microns).

9.

Open.suction.and.discharge.service.valves,.and.the.low.

pressure.transducer..Readjust.suction.bypass.valve.

10.

Close. disconnect. switches. for. the. compressor. motor.

starter.and.the.oil.pump.motor.starter,.if.applicable.

11.

.The.unit.is.ready.to.put.into.operation.

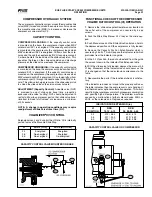

SUCTION CHECK VALVE BYPASS

A.1/4".angle.valve.(HV-1.on.P.&.I.diagram).is.installed.be-

tween.the.compressor.and.suction.flange.that.can.be.used.

as. a. suction. valve. bypass..This. feature. has. several. uses.

including.reducing.starting.torque,.improving.oil.quality,.and.

relieving.the.refrigerant.to.low.side.for.servicing.

In.most.cases,.the.valve.should.be.left.open.approximately.

1/4.to.1/2.turn.at.all.times..If.the.compressor.back-spins.or.

too.much.oil.foaming.is.experienced.while.venting,.partially.

close.valve.to.slow.speed.of.equalization..If.system.is.on.AUTO.

CYCLE.and.short.cycling.occurs,.the.valve.must.be.closed.

To.relieve.refrigerant.to.low.side,.close.separator.discharge.

service.valve..Slowly.open.bypass.valve.(if.closed).and.wait.

for.pressure.to.equalize..Close.bypass.and.suction.service.

valves.before.evacuating.the.unit.

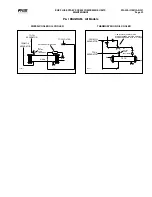

OIL FILTER - SINGLE

To.change.the.filter.cartridge.proceed.as.follows:

This.section.provides.instructions.for.normal.maintenance,.

a. recommended. maintenance. program,. troubleshooting.

and.correction.guides,.typical.wiring.diagrams,.and.typical.

P.and.I.diagrams.

THIS SECTION MUST BE READ AND

UNDERSTOOD BEFORE ATTEMPT-

ING TO PERFORM ANY MAINTE-

NANCE OR SERVICE TO THE UNIT.

CLOSE ALL COMPRESSOR PACK-

AGE ISOLATION VALVES PRIOR TO

SERVICING THE UNIT. FAILURE TO

DO SO MAY RESULT IN SERIOUS INJURY.

NORMAL MAINTENANCE OPERATIONS

When performing maintenance you

must take several precautions to

ensure your safety:

1.

. If.the.unit.is.running,.push

[STOP]

key.to.shut.down.the.

unit.

2.

Disconnect.power.from.unit.before.performing.any.main-

tenance.

3.

Wear.proper.safety.equipment.when.the.compressor.unit.

is.opened.to.the.atmosphere.

4.

. Ensure.adequate.ventilation.

5.

Take.necessary.safety.precautions.required.for.the.refrig-

erant.being.used.

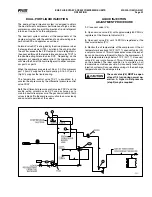

COMPRESSOR SHUTDOWN and START-UP

For seasonal or prolonged shutdown, the following

procedure should be used:

1.

.Push

[STOP]

key.to.shutdown.the.unit.

2.

. Open. the. disconnect. switch. for. the. compressor. motor.

starter.and.oil.pump.motor.starter.(if.applicable)..

3.

Turn.off.power..

4.

Close. suction,. discharge,. suction. check. valve. bypass,.

and.liquid.injection.service.valves..Attach.CLOSED.TAGS..

5.

Shut.off.cooling.water.supply.valve.to.the.oil.cooler,.if.ap-

plicable..Attach.CLOSED.TAG..

6.

Protect.the.oil.cooler.from.ambient.temperatures.below.

freezing.or.remove.the.water.heads.

NOTE: The unit should be inspected weekly during shut-

down. Check for leaks or abnormal pressure. Manually

rotate the compressor. Consult motor manufacturer for

recommendations.

To start up after a seasonal or prolonged shutdown, the

following procedure should be used:

1.

. Perform. routine. maintenance.. Change. oil. and. replace.

filters..Check.strainers.

2.

Any.water.necessary.for.the.operation.of.the.system.that.

may. have. been. drained. or. shut. off. should. be. restored. or.

turned. on.. If. the. oil. cooler. heads. were. removed,. reinstall.

and.remove.tags..