RXB PLUS ROTARY SCREW COMPRESSOR UNITS

INSTALLATION

070.101-IOM (JAN 13)

Page 10

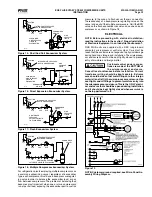

LIQUID INJECTION OIL COOLING

The.liquid.injection.system.provided.on.the.unit.is.self-con-

tained.but.requires.the.connection.of.the.liquid.line.sized.as.

shown.in.the.table.and.careful.insertion.of.the.expansion.valve.

bulb.into.the.thermowell.provided.in.the.separator..High.pres-

sure.gas.is.connected.through.the.regulator.to.the.external.

port.on.the.liquid.injection.valve.to.control.oil.temperature..

Refer.to.the.liquid.injection.piping.diagram.

NOTE: For booster applications, the high pressure gas

connection must be taken from a high side source (high-

stage compressor discharge). This should be a minimum

3/8" line connected into the solenoid valve provided. This

gas is required by the expansion valve external port to

control oil temperature.

High-stage.compressor.units.may.be.supplied.with.single-

port.(low.Vi).or.dual-port.(low.Vi.and.high.Vi),.liquid.injection.

oil.cooling..Single.port.will.be.furnished.for.low.compression.

ratio.operation.and.dual.port.for.high.compression.ratio.opera-

tion..Booster.compressor.units.use.single-port,.liquid.injection.

oil.cooling.due.to.the.typically.lower.compression.ratios.

The.control.system.on.high-stage.units.with.dual-port,.liquid.

injection.oil.cooling.switches.the.liquid.refrigerant.supply.to

the.high.port.when.the.compressor.is.operating.at.higher.

compression.ratios.(3.5.Vi.and.above).for.best.efficiency.

The. following. table. gives. the. condensing. temperature(s).

with. the. corresponding. maximum. evaporator. temperature.

limit.for.liquid.injection.usage.and.the.minimum.evaporator.

temperature.for.a.single-port.application.

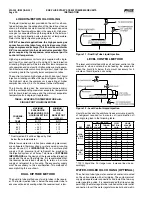

TABLE - EVAPORATOR TEMPERATURE with

SINGLE-PORT LIQUID INJECTION

CONDENS-

ING

TEMP

MAXIMUM

EVAPORATOR

TEMPERATURE FOR

LIQUID INJECTION

USAGE

MINI MUM *

EVAP TEMP

FOR

SINGLE PORT

(LOW Vi)

R-717

R-717

75°F

+10°F

-23°F

85°F

+25°F

-17°F

95°F

+35°F

-11°F

105°F

+40°F

-.4°F

*. Dual.Injection.Kit.will.be.shipped.by.Frick.

below.these.temperatures.

Where.low.compres.sion.ratios.(low.condensing.pressures).

are.anticipated,.thermo.syphon.or.water-cooled.oil.cooling.

should. be. used.. It. is.

IMPERA TIVE

. that. an. uninterrupt.ed.

supply. of. high. pres.sure. liquid. refrig.erant. be. provided. to.

the. injection. system. at. all. times..Two. items. of.

EXTREME

IMPORTANCE

.are.the.design.of.the.receiver/liquid.injection.

supply.and.the.size.of.the.liquid.line..It.is.recommended.that.

the. receiver. be. oversized. sufficiently. to. retain. a. 5. minute.

supply.of.refrigerant.for.oil.cooling..The.evaporator.supply.

must. be. secondary. to. this. considera.tion..Two. methods. of.

ac.complishing.this.are.shown.

DUAL DIP TUBE METHOD

The.dual.dip.tube.method.uses.two.dip.tubes.in.the.re.ceiv-

er..The.liquid.injection.tube.is.below.the.evaporator.tube.to.

ensure.continued.oil.cooling.when.the.receiver.level.is.low.

Figure 11 - Dual Dip Tube Liquid Injection

LEVEL CONTROL METHOD

The.level.control.method.utilizes.a.float.level.control.on.the.

receiver. to. close. a. solenoid. valve. feeding. the. evapora.tor.

when. the. liquid. falls. below. that. amount. necessary. for. 5.

minutes.of.liquid.injection.oil.cooling.

Figure 12 - Level Control Liquid Injection

Liquid.line.sizes.and.the.additional.receiver.volume.(quantity.

of. refrigerant. required. for. 5. minutes. of. liquid. injection. oil.

cooling).are.given.in.the.following.table:

REF

RXB

MODEL

LIQ. LINE SIZE*

FLOW

RATE (lb.)

5 MIN

LIQUID

VOLUME

CU.FT.

PIPE

SCH 80

TUBING

OD

HIGH

STAGE

R-717

12

1/2

–

10

.3

15

1/2

–

12.5

.4

19

1/2

–

15

.4

24

1/2

–

20

.6

30

1/2

–

25

.7

39

1/2

–

30

8

50

3/4

–

40

1.1

BOOST-

ER

R-717

12

1/2

–

2

.1

15

1/2

–

2.5

.1

19

1/2

–

3.5

.1

24

1/2

–

4.5

.1

30

1/2

–

5.5

.2

39

1/2

–

6.5

.2

50

1/2

–-

8.5

.3

*

.100.ft..liquid.line...For.longer.runs,.increase.line.size.ac-

cordingly.

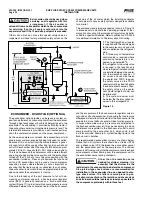

WATER-COOLED OIL COOLING (OPTION AL)

The.shell.and.tube-type,.water-cooled.oil.cooler.is.mounted.

on.the.unit.complete.with.all.oil.piping..The.customer.must.

supply.adequate.water.connections.and.install.the.two-way.

water.regulating.valve..It.is.recom.mended.that.(local.codes.

permitting).the.water.regula.tor.be.installed.on.the.water.outlet.

connection..Insert.the.water.regulator.valve.bulb.and.well.in.