DINAMAP*

Compact

Vital Signs Monitor

23

code output. Pressing the rotor operates a push button switch. These rotor control signals and the four

push buttons are encoded together on the switch board 8640AB by a register latch IC2. The register is

periodically polled by the system processor to determine if any of the switches have been operated.

IC2 is controlled by the chip select signal KEY_CS and the read signal LD_RD. KEY_CS is produced

by the Main Board chip select decoder IC16 under control of the system processor, while LD_RD

comes from the processor.

The ambient light detection circuit comprises of the light dependant resistor LDR1 and a bias resistor in

a potential divider configuration. A change in the level of incident light on the LDR1 causes its

resistance to alters, changing the voltage applied to the PIC ADC which determines the ambient light

level. The system processor regularly requests the ambient light level measurements from the PIC,

and in turn controls the brightness of the LED displays on the display board.

2.4.10 Displays

All displays, except for line power indicator, are multiplexed, and are split into three separate control

circuits, each with its own display driver. The power / charging green LED is controlled by the PIC

software.

The three LED display drivers (IC1, 2 & 3 on the display board) are Maxim MAX7219’s which are

controlled by the system processor via the SPI bus. The LED parameter displays are divided into

functional groups on the display board. IC1 drives the systolic and diastolic displays; IC2, the

Temperature and MAP displays; IC3, the Heart Rate and SpO

2

displays as well as the battery, °C, °F

and Heart discrete indicators. A current limiting resistor attached to iSET input of each driver IC sets

the maximum segment current in the display; each current limiting resistor is different because each

driver IC controls different sized LEDs. IC3 drives red and amber seven segment displays as well as

red and amber discrete displays, additional low value resistors or links R1 to R11 are inserted in series

with the anode of each diode to provide different LED currents within the same multiplex group.

The display drivers are all controlled by the system processor via the SPI bus data signal SPTXD. This

transmits the display data and controls the brightness of the displays by varying the multiplexer’s PWM

ratio. Data is latched into each driver ICs when the respective load signal LED_LOAD0-2 is pulled high

by decoder IC17 on the Main Board. This is synchronised with the LED SPI clock signal LED_CLK

from the system processor.

Text and graphical data is displayed on the LCD graphics module which contains its own on-board

driver electronics. The module is controlled by the system processor via filtered data bus DB0 ~ DB7,

address signal A4, RESET and the LCD_CS, LD_WE and LD_RD lines. The LCD_CS line is produced

by the Main Board chip select decoder IC16, while the LD_WE and LD_RD lines are derived from the

system processor’s R/W and CS and logic ICs IC1 & IC27.

Backlight illumination of the LCD is provided, the green LED source being under software control via

the system processor. The BACKLIGHT signal is decoded on the Main Board and used to turn on an

N-channel FET TR1 on the display board. A resistor sets the current and hence the constant backlight

brightness.

The LCD module requires the +5VD and -VLCD supplies to function. The -VLCD supply is derived

from the -12VR supply and can be trimmed by potentiometer RV1 on the switch board 8640AB. This

adjusts the effective viewing angle or contrast of the LCD display. The trimmed voltage is nominally

set to -9.6V and may be measured across TP1 and TP2 of the switch board.

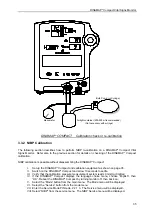

2.4.11 Printer

The monitor employs an Axiohm HPT4050 thermal printer module, fitted to the printer board which

contains the interface electronics. The PIC provides stepper motor control signals M_OE, M_PHASE1

and M_PHASE2 to IC3 on the printer board. This converts these to sequential drive signals MP1_1,

MP1_2, MP2_1 and MP2_2 for the stepper motor.

The PIC also sends a PRINTER_TRIGGER signal to initiate printer action, this triggers a timer IC4

which generates the printer enable signal PRINTER_OE. To optimise print speed, print quality and the