Issue: 01.06.2023

Page 6

•

Suction pipework should slope gently back towards the

unit to assist oil return to the compressor. A fall of

approximately 2cm per meter of pipework is

acceptable.

•

The maximum recommended pipe length is 50m.

•

Additional oil may be required if piping length

exceeds 20m or multiple oil traps are fitted. Check the

oil level closely during commissioning and add oil, as

necessary. Add oil in small amounts.

Do not overfill

the compressor!

•

It is recommended to install Pressure Relief Valve on

the liquid receiver if there is a risk of fire incidence.

Increasing temperature will lead to pressure increase in

receiver.

•

No valves and detachable joints shall be in areas

accessible to the public except when they comply with

EN 16084.

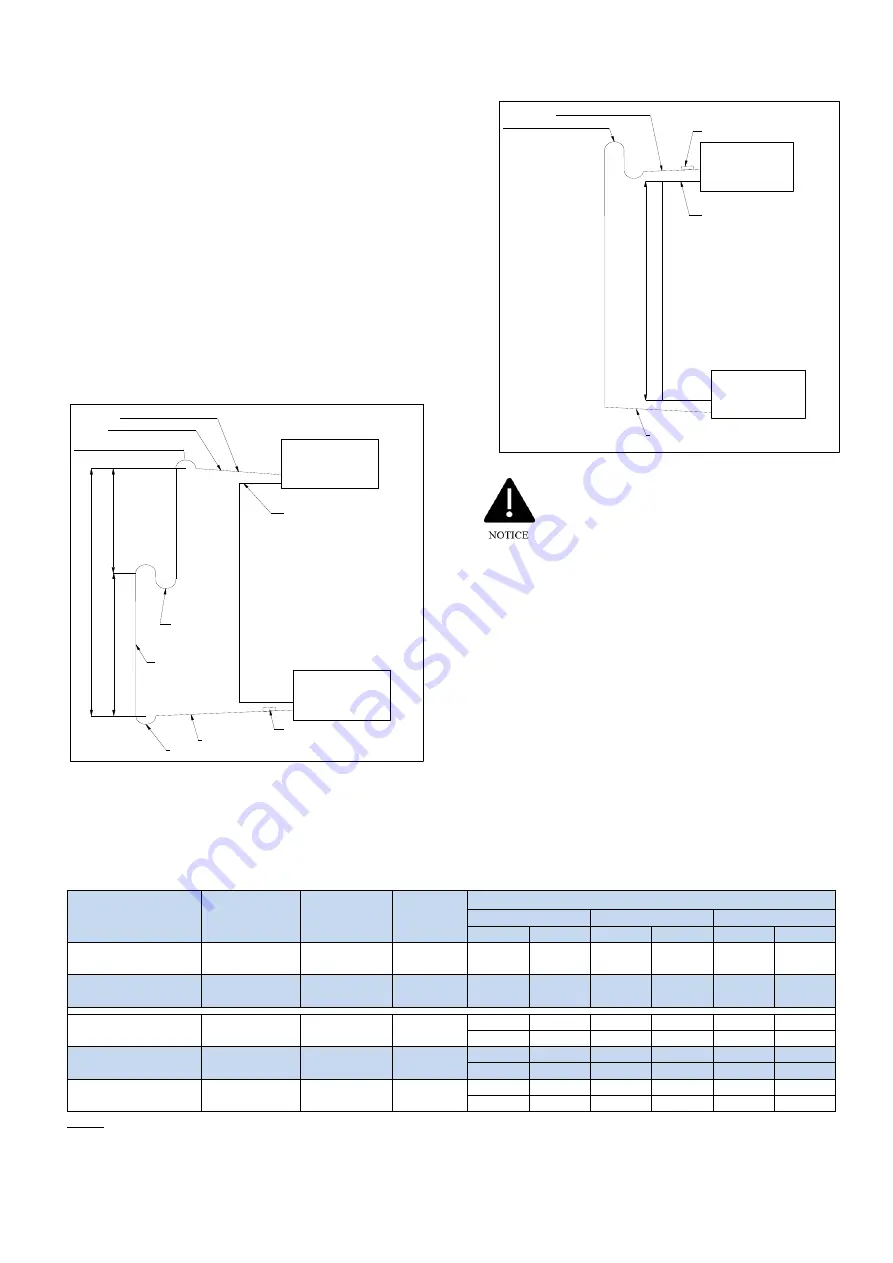

Figure 6 Piping Layout for Outdoor Above

Indoor

Figure 7: Piping Layout for Outdoor Below

Indoor

One of the main factors affecting equipment

reliability and compressor service life is

refrigeration circuit contamination.

During installation, circuit contamination could cause by:

•

Brazing and Welding Oxides

•

Filings and Particles from de-burring pipework

•

Brazing Flux

•

Moisture & Air

Pipe Sizing

When refer

Table 6

for selecting the connecting pipe size, the total equivalent length must include elbows and other components

that would increase the equivalent length.

Table 6: Total Equivalent Length

Notes:

(1)

The pipe sizes indicated in bold are from condensing unit to ‘T’ piece.

(2)

The pipe sizes indicated in brackets

are from ‘T’ piece to each evaporator.

(3)

Pipework should be selected on the total equivalent length of run between units.

(4)

For pipe sizing on runs longer than 30m, please contact J & E Hall.

INDOOR

UNIT

OUTDOOR

UNIT

MAX. 4m

MAX. 4m

8 TO 12 m/s

U-TRAP AS SHORT AS POSSIBLE

2cm/m SLOPE,

4m/s OR MORE

SUCTION LINE

LIQUID LINE

2cm/m SLOPE, 4m/s OR MORE

MAX. TOTAL HEIGHT <10M

BULB LOCATION

U-TRAP AS

SHORT AS

POSSIBLE

INVERTED P-TRAP

OUTDOOR

UNIT

INDOOR

UNIT

INVERTED P-TRAP

SUCTION LINE

LIQUID LINE

MAX. RISE 6M

2cm/m SLOPE, 4m/s OR MORE

BULB LOCATION

Liquid

Suction

Liquid

Suction

Liquid

Suction

3/8"

3/4"

3/8"

7/8"

3/8"

7/8"

(2x 3/8")

(2x 5/8")

(2x 3/8")

(2x 5/8")

(2x 3/8")

(2x 5/8")

1/2"

7/8"

1/2"

7/8"

1/2"

7/8"

(2x 3/8")

(2x 5/8")

(2x 3/8")

(2x 5/8")

(2x 3/8")

(2x 5/8")

1/2"

7/8"

1/2"

7/8"

1/2"

1 1/8"

(2x 3/8")

(2x 3/4")

(2x 3/8")

(2x 3/4")

(2x 3/8")

(2x 3/4")

- The pipe sizes indicated in brackets are from the ' T ' piece to each evaporator.

- Pipework should be selected on the total equivalent length of run between all units.

Condensing Unit

Model

Evaporator

Models

1x JCC2-80EV

1x JCC2-80EV

2x JCC2-60EV

BSCU-40-M1/M3

10m

20m

30m

CellarPlus 90-T1/T3

BSCU-30-M1/M3

BSCU-35-M1/M3

BSCU-30-M1/M3

BSCU-35-M1/M3

CellarPlus 70-S1/S3

3/8"

7/8"

CellarPlus 70-T1/T3

2x JCC2-40EV

3/8"

7/8"

CellarPlus 80-S1/S3

1/2"

7/8"

1/2"

System

- The pipe sizes indicated in

bold

are from condensing unit to ' T ' piece.

CellarPlus 80-T1/T3

7/8"

3/4"

3/8"

7/8"

2x JCC2-50EV

Pipe Sizing: 10ºC Cellar R448A/R449A

1/2"

1x TE2-03

1x TE2-04

TEV Model

2x TE2-02

2x TE2-02

2x TE2-02

Summary of Contents for CellarPlus 70-S1/S3

Page 26: ...Issue 01 06 2023 Page 23 Figure 30 Declaration of Conformity Outdoor ...

Page 27: ...Issue 01 06 2023 Page 24 Figure 31 Declaration of Incorporation Indoor ...

Page 28: ...Issue 01 06 2023 Page 25 Figure 32 Declaration of Incorporation Outdoor ...

Page 29: ...Issue 01 06 2023 Page 26 Figure 33 EU Declaration of Conformity Outdoor ...

Page 30: ...Issue 01 06 2023 Page 27 Figure 34 EU Declaration of Incorporation Indoor ...

Page 31: ...Issue 01 06 2023 Page 28 Figure 35 EU Declaration of Incorporation Outdoor ...