M A I N T E N A NC E

Page 41

F I L L I N G A N D A D J U S T I N G O I L E R

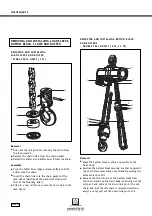

The oiler ensures that the hoist air supply is consistently

provided with a precisely-metered quantity of oil.

Regular checking of the oiler is very important, as the

vane motor may be damaged in the case of lubricant

deficiency. The oiler can also be refilled under pressure.

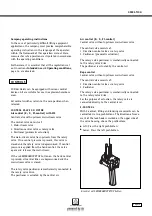

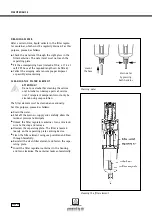

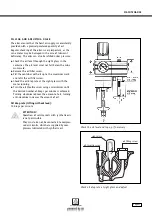

Check the oil level through the sight glass in the

container. The oil level must not fall below the mini-

mum mark.

Remove the oil filler screw.

Fill the container with oil up to the maximum mark

and refit the oil filler screw.

Check the oil drop rate at the sight glass with the

motor running.

Turn the oil throttle screw using a screwdriver until

the desired number of drops per minute is achieved.

Turning clockwise reduces the amount of oil; turning

anti-clockwise increases the amount of oil.

Oil drop rate (lifting without load):

10 drops per minute

AT T E N T I O N !

Operation of service units with synthetic oils

is not permissible.

They must also not be connected to compres-

sed air circuits, which are supplied by com-

pressors lubricated with synthetic oil.

Check oil drop rate at sight glass and adjust

sight glass

oil throttle screw

oil filling screw

Check the oil level and top up if necessary