M A I N T E N A NC E

Page 34

M A I N T E N A NC E

JDN Air Hoists are extremely robust and require little

maintenance. Compliance with maintenance and inspec-

tion intervals is of great importance, in order that the

hoist operates safely and reliably over a period of many

years. It is essential that the intervals are shortened

under particularly wear-promoting operating conditions.

C AU T I O N !

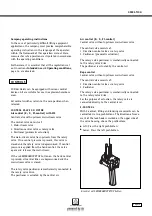

Maintenance work on JDN Air Hoists must

only be performed by trained and qualified

personnel.

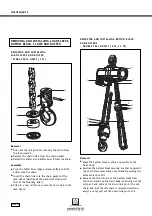

If your JDN Air Hoist is often used at different locations,

particularly in dirty and damp environments,

clean the hoist and the chain of dirt contamination,

seal off the air supply connections,

store the hoist in a clean and dry place.

If, during repair work, the replacement of components

is necessary, only original JDN spare parts may be

installed.

(see section

Lubricants,

page 25)

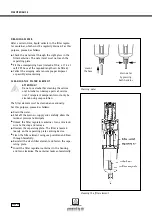

Series lifting equipment is classified into groups and

dimensioned according to the type of operation (Driving

mechanism classification according to ISO/FEM). The

classification (M3/1 Bm) is determined by the average

daily operating time (max. 1 hour) and the load spec-

trum. The theoretical operating time for load spectrum

2 (average) is 1600 hours. This corresponds to 400 full-

load hours. This is provided that the lifting and lowe-

ring paths are approximately the same.

For devices used mainly in vertical operation (from 75 %

of on-time), the theoretical operating time is reduced

due to the higher lowering speed in the range from

50 % to 100 % of the nominal load.

Therefore, the determined portion of the theoretical

operating time must be multiplied by a factor of f

v

.

The factor f

v

has a value of 1 to 50 % of the nominal

load, increasing linearly to 1.5 at 100 % of the nominal

load (nominal load percentage P).

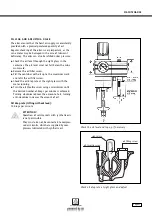

In order to achieve safe operating periods, the company

must check that the theoretical operating time has been

achieved during each inspection, by the person respon-

sible. This must be documented in the inspection log at

least once annually. The inspection log contains a

model for determining the actual operating time.

A general overhaul must be performed, when the theo-

retical operating time has been achieved. Detailed

explanations for the determination of the actual opera-

ting time and its documentation can be found in the

national safety regulations. The general overhaul must

be initiated by the operator and must be documented in

the inspection log. Information on general overhaul can

be requested from the manufacturer.

f

v

= 1+ 0,5

P-50

50

(for P > 50%)

I N S P E C T I O N A N D R E PA I R S

L U B R I C A N T S

S PA R E PA R T S

C L E A N I N G A N D C A R E

M A I N T E N A N C E A N D

I N S P E C T I O N I N T E R VA L S