AC C E S S O R I E S

Page 55

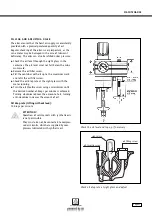

In the case of a control hose length exceeding 10 m,

the reaction times of the lever controls increase

significantly.

Consequently, a booster unit is generally installed on

the motor for controls E, F and FI, enabling normal

reaction times.

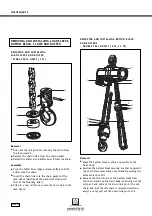

For various areas of application, a chain box enhances

operational safety, i.e. when a chain which is hanging

down could become caught up with the load.

JDN chain boxes are available in various sizes, corres-

ponding to the chain lengths.

AT T E N T I O N !

Do not exceed the permissible filling capacity.

Danger of chain dropping.

AT T E N T I O N !

Loads must not be moved against the chain

box during lifting. If necessary, attach a

clamp to the chain.

The clamp must be attached above the load hook so

that it functions as a preliminary end stop. With the

and

(double fall) the clamp

must be positioned as far as necessary downwards on

the reeved chain in order to support the bottom block

(stationary chain).

In addition, a spacer must be attached to the opposite

(moving) chain above the buffer in order to relocate the

stroke limiter. Please contact us, if required.

For greater clarity, see the lower illustration

on page 44.

In all cases, a clamp is attached in the 10th chain link

of the unloaded chain end so that a length of chain

remains in the chain box when the bottom load hook

position is reached. Thus, the chain cannot run next to

the chain box during subsequent lifting (see section

Removing and installing chain

page 50).

AT T E N T I O N !

Never allow the chain to pile up in the

chain box.

After installing the chain box, lower the load hook to

the bottom position once.

Then activate lifting movement and run the complete

chain into the chain box.

DA N G E R !

During operation with the chain box,

lubrication of the chain is particularly impor-

tant in order to prevent it from piling up and

falling out. Do not install longer chains when

changing chains.

10

6

C H A I N B OX

B O O S T E R U N I T