M A I N T E N A NC E

Page 50

AT T E N T I O N !

The chain supplied together with this JDN

hoist is matched to the chain sprocket accor-

ding to strict tolerances. In order to ensure

optimum function of the chain and in order

to prevent hazards, only genuine JDN chains

must be installed.

Note:

When a chain is replaced, the buffers must also

be replaced. For changing buffers at the chain ends, see

section

"Removing and installing load sleeve, bottom

block, clamp and buffer"

.

The buffers located within the chain are most easily

replaced when the open chain link between the old and

new chains passes the buffer to be replaced.

AT T E N T I O N !

Do not twist the chain ends.

In the case of operation with a chain box:

switch the hoist in the "lower" rotational direction

and run the old chain out of the chain box.

Then remove the chain box.

Move the bottom block as close as possible to the

hoist body and position it securely.

In the case of hoists without chain box, detach the

idle chain from the chain mount – for double fall

hoists, the bottom block chain is released simultane-

ously – (see also section

"Removing and installing

load sleeve, bottom block, clamp and buffer"

).

Detach the clamp, buffer and buffer discs from the

end of the idle chain.

For single fall hoists,

also detach the load sleeve,

buffer and buffer discs from the load chain.

For double fall hoists

with chain box, detach the

bottom block from the hoist body.

For treble fall hoists,

detach the bottom block chain

from the mount on the bottom block. (see also section

"Removing and installing load sleeve, bottom

block, clamp and buffer"

).

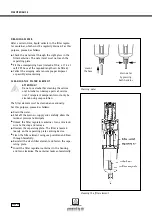

Attach the new chain to the end link of the load

section of the old chain after aligning the welds and

the first chain link by means of an open chain link.

The welds on the upright chain links must face out-

wards when running over the chain sprockets. For

this reason, the welds of the chain links which lie

flat in the drive sprocket must face towards the gear-

box. If the first link of the new chain is not correctly

positioned, it must be removed.

Note:

It is possible that the first chain link of the other

chain end is correctly positioned.

Switch the hoist to the "lift" rotational direction.

The new chain will now run into the hoist while the

old chain is simultaneously run out on the idle

chain side.

Run the chain until the join between the old and new

chain has run sufficiently (approx. 1m) out of the centre

section on the idle chain side.

Detach the connection between the old and new

chains.

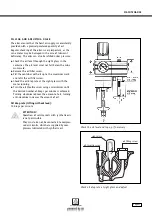

Install the clamp (at the 10th chain link), buffer and

buffer discs on the idle chain section of the new chain.

Only in the case of operation without chain box, align

the idle chain and attach to the fastening point on the

hoist – for double fall hoists, the bottom block chain is

also attached here later – (see also section

"Removing

and installing load sleeve, bottom block, clamp and

buffer"

.

Attach the chain box if necessary.

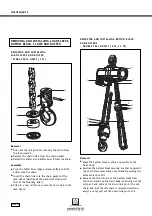

Switch the hoist in the "lift" rotational direction

until the as yet free end of the

aligned

load chain is

the correct length for attaching the chain link,

–

for single fall hoists

in the load sleeve after the

buffer and buffer discs have been pushed on,

–

for double fall hoists

at the fastening point on

the hoist body and

–

for treble fall hoists

at the fastening point of

the bottom block (see also section

"Removing and

installing load sleeve, bottom block, clamp and

buffer"

).

Note

: If the chain link of the load chain is positioned

incorrectly, it must be removed, the following chain link

will be positioned correctly.

R E M O V I N G A N D I N S TA L L I N G C H A I N