I N I T I A L O P E R AT I O N

Page 22

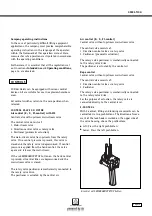

Control valve (on motor)

Note: In order to connect the hoses to the control

valve, we recommend removal of the hose adapter.

Remove the hose adapter (secured via central bolt).

Attach the hoses to the corresponding nipples

(see designation in illustration)

Secure the hoses using the one-ear hose clamps and

crimping tool.

Secure the strain-relief rope.

AT T E N T I O N !

The strain-relief rope must be installed with

the correct length, in order to prevent loading

of the hoses.

Pull the bellows over the hose adapter.

The upper collar of the bellows fits into the recess of

the hose adapter.

In order to secure the hose adapter to the control

valve, a long A/F 6 socket spanner must be guided

between the three hoses, through the middle of

the bellows and inserted into the hexagon socket of

the bolt.

F - CO N T R O L C O N N E C T I O N

Pull the bellows over the hose bundle for F-control. For

F-control for lifting and lowering only, remove approx.

80 mm of hose bundle protective sheathing; for F-con-

trols with additional functions (trolley/crane movement)

remove approx. 160 mm from end of protective sheathing.

Pull the strain-relief ropes through the eye bolt

and secure using rope clamps.

Insert the control hoses:

See illustration above

Compressed air

with hose designation 1 or colour: white

Movement direction "lift"

hose designation 2 or colour: green

Movement direction "lower"

hose designation 3 or colour: red

Bellows with A/F 6 socket spanner

Hose adapter with nipples designation lift, lower

Dowel pin

Raise

Compressed air

connection

Lower