M A I N T E N A NC E

Page 38

DA N G E R !

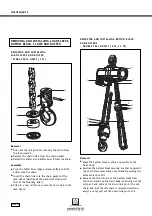

The fatigue strength of chains is significantly

impaired due to extreme corrosion (pitting

corrosion). There is a

danger of fracture

.

Hydrogen-induced embrittlement with

resultant stress cracks due to highly corrosive

media (e.g. seawater) may affect high-

strength steels (e.g. chains). Danger of

fracture! This process is promoted by so-cal-

led recombination poisons. Examples of these

are hydrogen sulphide, cyanide, arsenic com-

pounds and rhodanide.

Furthermore, hazards arise due to rusty

chains when operating with chain boxes,

as the chain can form a heap and fall over

the edge of the container rim. In addition,

rusty chains are subject to extreme wear.

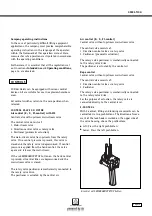

The chains of JDN Air Hoists must be lubricated in the

links, in unloaded condition.

Clean heavily contaminated chains.

Lay the chain in a suitable container.

Spray the chain with motor vehicle engine oil.

If you wish to lubricate the hanging chain, ensure

that the chain links are oiled at the points of contact.

For this purpose, move the chain to and fro.

A high-performance lubricant in an aerosol can is avai-

lable from JDN, which adheres well to the chain after

the solvent has evaporated and does not drip off, Art.

no. 12066 (aerosol 400 ml).

For operation in areas with high corrosion potential,

e.g. in the off-shore sector, the chain can be largely pro-

tected against corrosion by the use of special lubricants.

These types of lubricants are characterised by weathering

resistance, water insolubility, good adhesion properties etc.

Re-lubrication intervals must be stipulated in accordan-

ce with the loading.

Please contact us, if required.

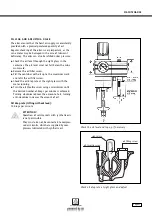

The control elements of the controls must

always be easily moving.

Unload the JDN Air Hoist.

Briefly actuate and release all control elements of the

controls one after another. The control elements must

return to their initial positions immediately.

Press the EMERGENCY STOP button. Each movement of

the hoist must stop. Actuation of the control elements

must not cause a lifting or lowering movement.

Release the EMERGENCY STOP button by turning.

DA N G E R !

If a control element is stiff or remains in

the actuated position, do not use the hoist.

The controls must be repaired.

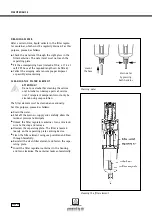

Independent of the stipulated inspection intervals, the

silencer must be checked for permeability if the hoist

does not achieve the specified lifting speed (see section

Technical data,

page 56).

The test is performed by comparing the lifting speeds

under nominal load, with and without the silencer.

The speed with standard silencer or filter silencer must

be at least 80 % of the lifting speed without a silencer

element.

In the case of lower values, the silencer elements

must be cleaned or replaced.

C H E C K I N G T H E

S I L E N C E R F O R P E R M E A B I L I T Y

C H E C K I N G C O N T R O L S

L U B R I C AT I N G T H E C H A I N