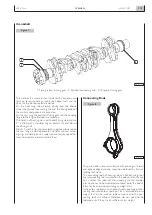

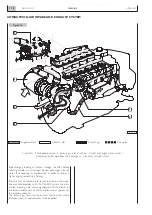

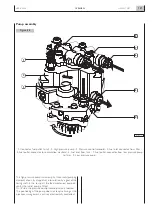

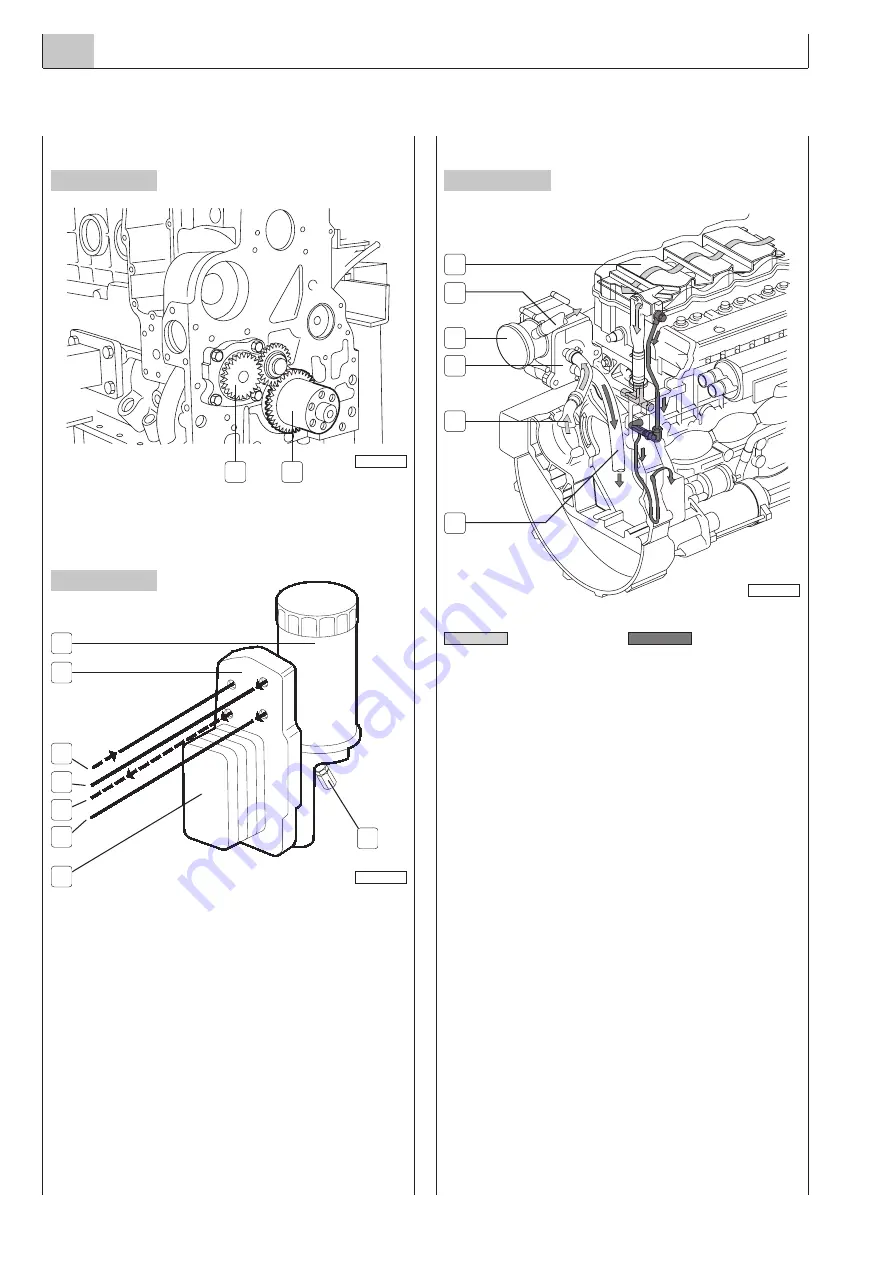

Gear Pump

1. Gear oil pump - 2. Crankshaft with driving gear oil pump.

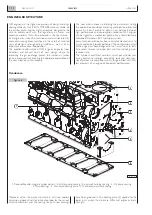

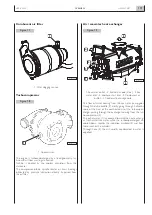

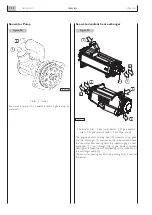

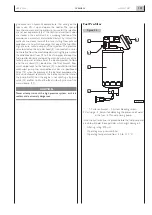

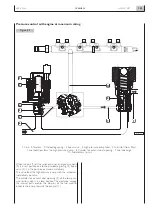

Filter bracket

1. Heat exchanger with engine coolant - 2. Oil delivery to

internal engine machine members - 3. Flow recirculated by

pressure regulator valve. - 4. Delivery to nozzles piston

cooling - 5. Flow inlet from the pump. - 6. Flange coupling

onto crankcase - 7. Oil filter - 8. Oil for turbocompressor

lubrication connector outlet.

On the rest the seating for the pressure valve adjustment

and the by-pass valve are machined. The ducts machined

inside enable to divert the oil inside the engine crankcase to

the different lubrication functions. The filter, single cartridge,

is two-stage with 5µm parallel filtering.

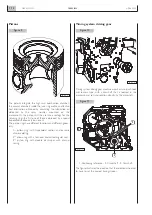

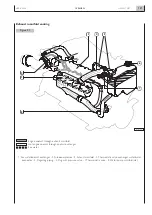

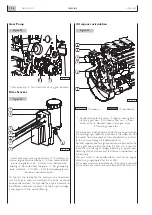

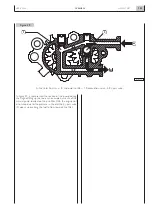

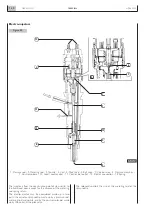

Oil vapour recirculation

1. Condensate oil to the sump. - 2.Vapours coming from

the timing gear box - 3. Oil vapour filter unit - 4. Flow

limiter valve - 5. Residual vapours to engine intake -

6. Centrifugal separator.

The oil vapours which generate inside the engine, go through

the centrifugal gas separator machined in the upper part of

the rocker lid, where some of them condensate and return

to the oil sump through the dedicated ducts.

Residual vapours, due to higher pressure are pushed to the

timing gear box and from there to the filter unit. In the unit

there are two filtering cartridges operating in parallel con-

densating a further vapour part that returns in liquid form to

the oil sump.

The part which is not condensated is sent to the engine

intake by a gauged hole after the air filter.

The vapour maximum load intaken by the engine is adjusted

by the action of a membrane valve located in the filter unit.

N60 ENT M37

OVERVIEW

1.26

APRIL 2004

04_037_N

04_190_N

1

2

6

7

8

1

Figure 29

Figure 30

2

3

4

5

Figure 31

04_038_N

Oil vapours

Oil condensate

1

2

3

4

5

6

Summary of Contents for N60 ENT M37

Page 4: ...N60 ENT M37 IV APRIL 2004 ...

Page 52: ...N60 ENT M37 OVERVIEW 1 52 APRIL 2004 ...

Page 54: ...N60 ENT M37 TECHNICAL DATA 2 54 APRIL 2004 ...

Page 60: ...N60 ENT M37 TECHNICAL DATA 2 60 APRIL 2004 ...

Page 62: ...N60 ENT M37 ELECTRICAL EQUIPMENT 3 62 APRIL 2004 ...

Page 92: ...N60 ENT M37 DIAGNOSTICS 4 92 APRIL 2004 ...

Page 116: ...N60 ENT M37 DIAGNOSTICS 4 116 APRIL 2004 ...

Page 118: ...N60 ENT M37 MAINTENANCE 5 118 APRIL 2004 ...

Page 122: ...N60 ENT M37 MAINTENANCE 5 122 APRIL 2004 ...

Page 124: ...N60 ENT M37 SERVICING OPERATIONS ON INSTALLED ENGINE 6 124 APRIL 2004 ...

Page 139: ...SECTION 7 TOOLS Page TOOLS 141 N60 ENT M37 TOOLS 7 139 APRIL 2004 ...

Page 140: ...N60 ENT M37 TOOLS 7 140 APRIL 2004 ...

Page 146: ...N60 ENT M37 TOOLS 7 146 APRIL 2004 ...

Page 156: ...APRIL 2004 OVERHAUL 8 156 N60 ENT M37 ...

Page 164: ...APRIL 2004 OVERHAUL 8 164 N60 ENT M37 ...

Page 181: ...OVERHAUL APRIL 2004 N60 ENT M37 8 181 ...

Page 188: ...N60 ENT M37 OVERHAUL 8 188 APRIL 2004 ...

Page 190: ...N60 ENT M37 SAFETY PRESCRIPTIONS 9 190 APRIL 2004 ...

Page 193: ......