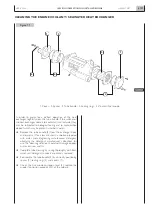

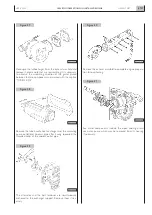

1. Piping for electro-injectors - 2. Common rail -

3. Piping for rail supply.

The high-pressure piping connects the high-pressure

pump, the rail (2) and the electro-injectors. Tubing is in

metal construction and coupled by means of hexagon nut

axial junctions.

WARNING

The high-pressure system may reach very high pressure

levels:

DO NOT ATTEMPT TO LOOSEN HYDRAULIC CON-

NECTIONS TIGHTENING ITEMS WITH ENGINE RUN-

NING.

Tighten axial junction nuts with a torque of 20 Nm.

WARNING

In case piping removal is necessary DO NOT REUSE IT

AND ALWAYS REPLACE IT WITH NEW PIPING.

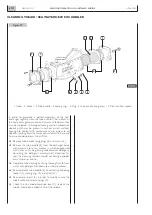

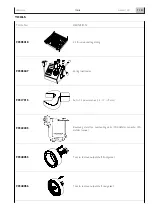

A.To rail supply - B. Return flow from rail

1. Rubber holder junction for fuel inflow from pre-filter -

2. Rubber holder junction for fuel outflow to the tank -

3. Fuel filter.

Engine piping completing the low pressure fuel system is in

metal construction. Coupling is done using eye junctions

secured using hexagonal screws.

Coupling water-tightness is obtained using copper washers.

In case piping removal is necessary, replace washers with

new ones when reassembling.

Tighten low-pressure junction screws with a torque of 12

Nm.

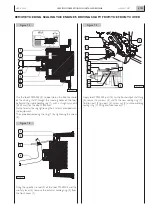

VENTING THE AIR FROM THE FUEL FEED

LOOP

To exhaust air from fuel system, operate the pre-filter man-

ual pump or use a specific electric pump.

Tighten the vent fitting and continue pumping during the ini-

tial start-up phases.

Make sure that the fuel that flows out of the fitting is not dis-

persed in the environment.

CAUTION

Never attempt to vent the high pressure system, as this is

useless and extremely dangerous.

N60 ENT M37

SERVICING OPERATIONS ON INSTALLED ENGINE

6.129

APRIL 2004

Figure 8

Figure 9

04_072_N

04_244_N

1

2

3

3

B

A

2

1

FUEL SYSTEM PIPING

Summary of Contents for N60 ENT M37

Page 4: ...N60 ENT M37 IV APRIL 2004 ...

Page 52: ...N60 ENT M37 OVERVIEW 1 52 APRIL 2004 ...

Page 54: ...N60 ENT M37 TECHNICAL DATA 2 54 APRIL 2004 ...

Page 60: ...N60 ENT M37 TECHNICAL DATA 2 60 APRIL 2004 ...

Page 62: ...N60 ENT M37 ELECTRICAL EQUIPMENT 3 62 APRIL 2004 ...

Page 92: ...N60 ENT M37 DIAGNOSTICS 4 92 APRIL 2004 ...

Page 116: ...N60 ENT M37 DIAGNOSTICS 4 116 APRIL 2004 ...

Page 118: ...N60 ENT M37 MAINTENANCE 5 118 APRIL 2004 ...

Page 122: ...N60 ENT M37 MAINTENANCE 5 122 APRIL 2004 ...

Page 124: ...N60 ENT M37 SERVICING OPERATIONS ON INSTALLED ENGINE 6 124 APRIL 2004 ...

Page 139: ...SECTION 7 TOOLS Page TOOLS 141 N60 ENT M37 TOOLS 7 139 APRIL 2004 ...

Page 140: ...N60 ENT M37 TOOLS 7 140 APRIL 2004 ...

Page 146: ...N60 ENT M37 TOOLS 7 146 APRIL 2004 ...

Page 156: ...APRIL 2004 OVERHAUL 8 156 N60 ENT M37 ...

Page 164: ...APRIL 2004 OVERHAUL 8 164 N60 ENT M37 ...

Page 181: ...OVERHAUL APRIL 2004 N60 ENT M37 8 181 ...

Page 188: ...N60 ENT M37 OVERHAUL 8 188 APRIL 2004 ...

Page 190: ...N60 ENT M37 SAFETY PRESCRIPTIONS 9 190 APRIL 2004 ...

Page 193: ......