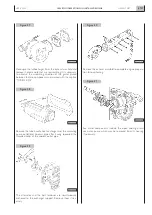

TOOLS

TOOL No.

DEFINITION

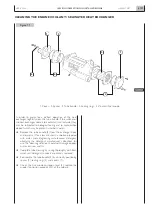

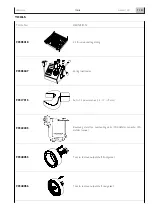

99360595

Lifting rig for engine removal/refitting

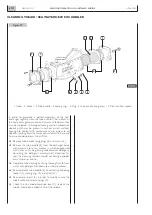

99360605

Band for fitting piston into cylinder barrel (60 — 125 mm)

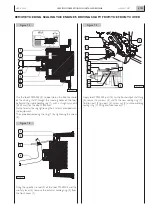

99361037

Brackets for fastening engine to revolving stand 99322205

99363204

Tool to remove gaskets

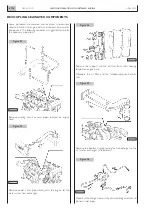

99370006

Handgrip for interchangeable beaters

99370415

Gauge base for different measurements (to be used with 99395603)

APRIL 2004

TOOLS

7.144

N60 ENT M37

Summary of Contents for N60 ENT M37

Page 4: ...N60 ENT M37 IV APRIL 2004 ...

Page 52: ...N60 ENT M37 OVERVIEW 1 52 APRIL 2004 ...

Page 54: ...N60 ENT M37 TECHNICAL DATA 2 54 APRIL 2004 ...

Page 60: ...N60 ENT M37 TECHNICAL DATA 2 60 APRIL 2004 ...

Page 62: ...N60 ENT M37 ELECTRICAL EQUIPMENT 3 62 APRIL 2004 ...

Page 92: ...N60 ENT M37 DIAGNOSTICS 4 92 APRIL 2004 ...

Page 116: ...N60 ENT M37 DIAGNOSTICS 4 116 APRIL 2004 ...

Page 118: ...N60 ENT M37 MAINTENANCE 5 118 APRIL 2004 ...

Page 122: ...N60 ENT M37 MAINTENANCE 5 122 APRIL 2004 ...

Page 124: ...N60 ENT M37 SERVICING OPERATIONS ON INSTALLED ENGINE 6 124 APRIL 2004 ...

Page 139: ...SECTION 7 TOOLS Page TOOLS 141 N60 ENT M37 TOOLS 7 139 APRIL 2004 ...

Page 140: ...N60 ENT M37 TOOLS 7 140 APRIL 2004 ...

Page 146: ...N60 ENT M37 TOOLS 7 146 APRIL 2004 ...

Page 156: ...APRIL 2004 OVERHAUL 8 156 N60 ENT M37 ...

Page 164: ...APRIL 2004 OVERHAUL 8 164 N60 ENT M37 ...

Page 181: ...OVERHAUL APRIL 2004 N60 ENT M37 8 181 ...

Page 188: ...N60 ENT M37 OVERHAUL 8 188 APRIL 2004 ...

Page 190: ...N60 ENT M37 SAFETY PRESCRIPTIONS 9 190 APRIL 2004 ...

Page 193: ......