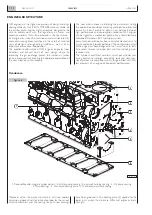

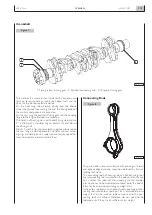

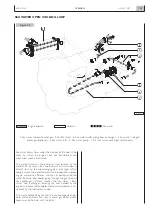

The crankshaft is made in steel hardened by induction and

rests on seven mountings; inside the hollow shaft are the

ducts for the lubrication oil circulation.

On the front tang, the oil pump driving gear, the phonic

wheel, the flywheel connecting hub and the driving pulley of

the ancillary components are keyed on.

On the rear tang the camshaft driving gear and the coupling

flange to the engine flywheel are keyed on.

The bench half bearing are in cast babbitt lining steel and the

6

th

is fitted with a shoulder ring to contain the end play of

the driving shaft.

Details 1 and 2 in figure,assembled by negative allowance on

the rear tang are not replaceable. The front and rear retain-

ing rings are slide type with radial seal and require special fix-

tures to assemble and disassemble them.

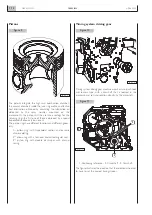

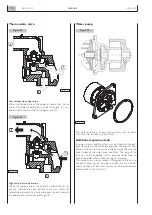

Connecting Rods

They are made in steel, manufactured by pressing with small

end oblique edged and cap separation obtained by fracture

splitting technique.

The connecting rod half bearings are cast babbitt lining steel.

Every connecting rod is marked on the body and on the cap

by a number that identifies their coupling and the cylinder

into where has to be assembled; moreover onto the body a

letter has been impressed stating its weight class.

In the case a replacement is necessary, only one type of con-

necting rod is available as spare part of an intermediate class

weight that can be used to replace anyone else. The con-

necting rods still efficient therefore, do not need to be

replaced even if they are of a different class weight.

N60 ENT M37

OVERVIEW

1.13

APRIL 2004

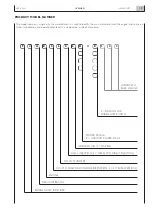

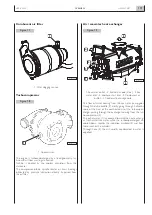

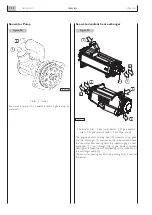

Figure 7

Crankshaft

1.Timing system driving gear - 2. Flywheel connecting hub - 3. Oil pump driving gear.

04_012_N

3

1

2

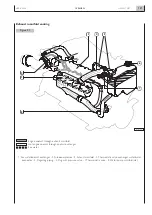

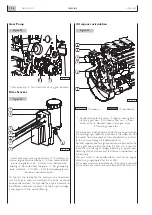

04_013_N

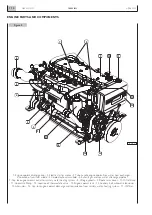

Figure 8

Summary of Contents for N60 ENT M37

Page 4: ...N60 ENT M37 IV APRIL 2004 ...

Page 52: ...N60 ENT M37 OVERVIEW 1 52 APRIL 2004 ...

Page 54: ...N60 ENT M37 TECHNICAL DATA 2 54 APRIL 2004 ...

Page 60: ...N60 ENT M37 TECHNICAL DATA 2 60 APRIL 2004 ...

Page 62: ...N60 ENT M37 ELECTRICAL EQUIPMENT 3 62 APRIL 2004 ...

Page 92: ...N60 ENT M37 DIAGNOSTICS 4 92 APRIL 2004 ...

Page 116: ...N60 ENT M37 DIAGNOSTICS 4 116 APRIL 2004 ...

Page 118: ...N60 ENT M37 MAINTENANCE 5 118 APRIL 2004 ...

Page 122: ...N60 ENT M37 MAINTENANCE 5 122 APRIL 2004 ...

Page 124: ...N60 ENT M37 SERVICING OPERATIONS ON INSTALLED ENGINE 6 124 APRIL 2004 ...

Page 139: ...SECTION 7 TOOLS Page TOOLS 141 N60 ENT M37 TOOLS 7 139 APRIL 2004 ...

Page 140: ...N60 ENT M37 TOOLS 7 140 APRIL 2004 ...

Page 146: ...N60 ENT M37 TOOLS 7 146 APRIL 2004 ...

Page 156: ...APRIL 2004 OVERHAUL 8 156 N60 ENT M37 ...

Page 164: ...APRIL 2004 OVERHAUL 8 164 N60 ENT M37 ...

Page 181: ...OVERHAUL APRIL 2004 N60 ENT M37 8 181 ...

Page 188: ...N60 ENT M37 OVERHAUL 8 188 APRIL 2004 ...

Page 190: ...N60 ENT M37 SAFETY PRESCRIPTIONS 9 190 APRIL 2004 ...

Page 193: ......