i-ALERT2 Application Guide

25 of 64

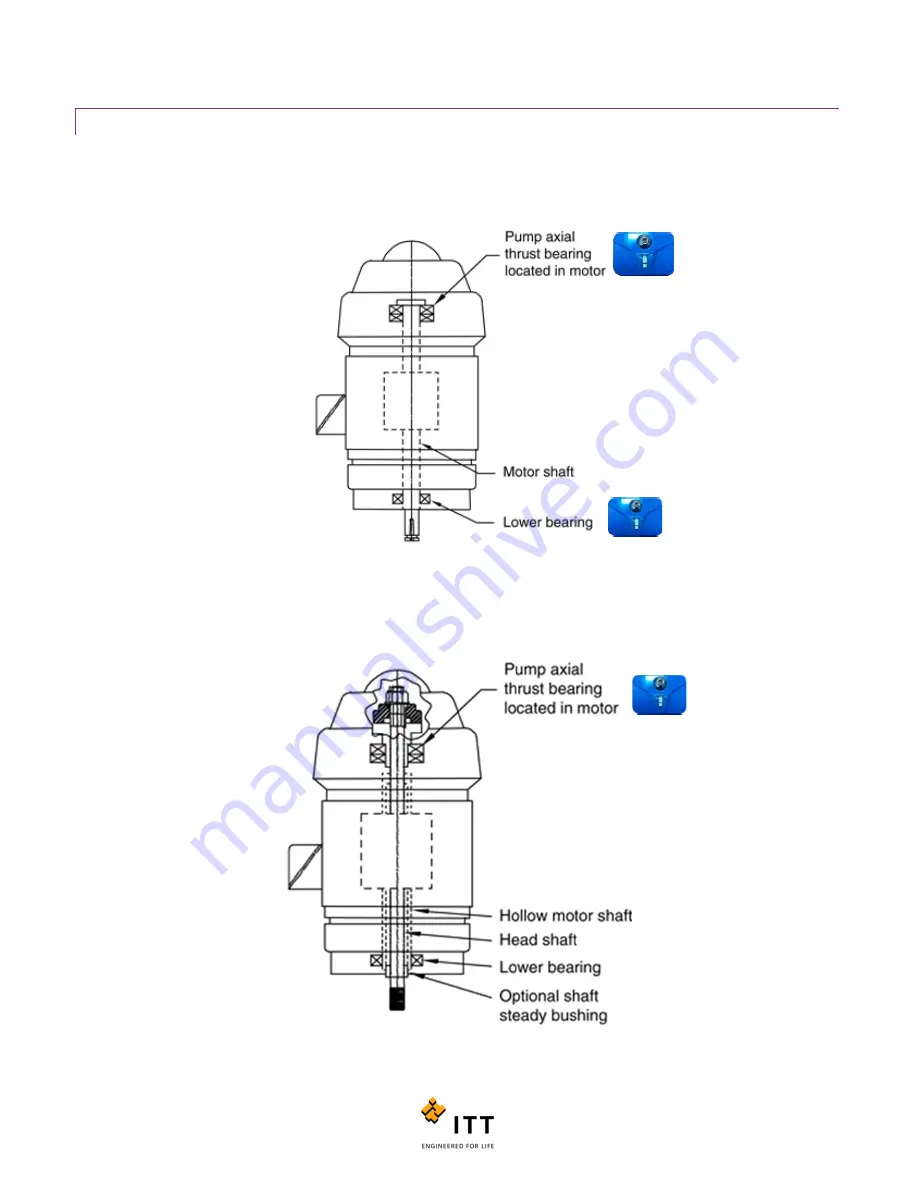

VERTICAL ELECTRIC MOTORS

The best mounting location for the i-ALERT2 device will depend on which class of vertical motor is being monitored. For

vertical solid shaft motors with 2 rigid bearings, instrument the upper thrust bearing housing first since this is the primary

bearing absorbing thrust loads. The lower bearing can also be instrumented if desired.

For vertical hollow shaft (VHS) motors it is recommended to mount the i-ALERT2 device adjacent to the thrust bearing at

the top of the motor. Most VHS motors do not have lower bearings and therefore there is no need for a second monitor.

Figure 20: Vertical Hollow Shaft Motor, at thrust bearing

Figure 19: Vertical Motor with 2 Bearings,

monitor at each bearing

Summary of Contents for i-ALERT2

Page 1: ...Application Guide...

Page 2: ...i ALERT2 Application Guide 2 of 64...

Page 32: ...i ALERT2 Application Guide 32 of 64 Figure 27 Devices in range and out of range...

Page 58: ...i ALERT2 Application Guide 58 of 64 Figure 57 Route Report Trend Details Screen...

Page 63: ...i ALERT2 Application Guide 63 of 64...

Page 64: ...i ALERT2 Application Guide 64 of 64 G iALERT2AppGuide en US 2016 10...