49

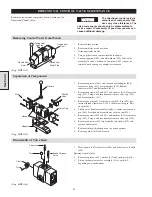

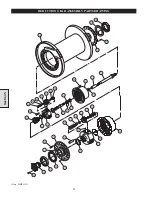

Intermediate Carrier Disassembly

rior to disassembly check planet gear side clearance, 0.005 to 0.032

inches (0.13 to 0.81 mm). Spin gears, gears should rotate freely. If

gears are tight or clearance is incorrect, disassemble planet

assembly.

(Dwg. MHP1169)

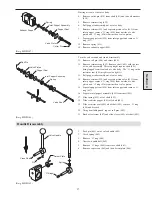

1.

Tap roll pin (50) completely into intermediate planet pin (46).

2.

Place carrier in a wide shallow container or on a clean shop

towel. Each gear contains 36 needle bearings (48) that may fall

out as the intermediate carrier is disassembled.

3.

Tap out intermediate planet pin (46). Remove thrust washers

(52, 55, and 64), needle bearings (48), and spacer (49). Thrust

washers (52, 55, and 64) are used in combination to achieve

clearance, all three might not be present or quantities may

vary.

4.

Tap roll pin (50) out of intermediate planet pin (46).

(Dwg. MHP1187)

Inspection

1.

Check all gear teeth for signs of galling, chipping, or uneven

wear pattern.

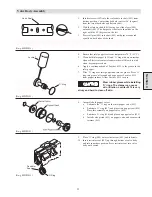

Intermediate Carrier Assembly

Cut two pieces of cardboard 3 inches (76 mm) square.

Make a intermediate planet pin tool as follows:

a. Cut an old pin to the same width as the gear, or

b. Make a pin that is the same diameter as intermediate planet

pin (46) and as long as the gear is wide.

1.

Place planet gear (51) on the cardboard square and insert pin

tool.

2.

Insert 5 to 7 needle bearings (48) into gear around pin tool,

ensure first few needle bearings do not tip over.

3.

Insert spacer (49) followed by all 18 needle bearings.

(Dwg. MHP1164)

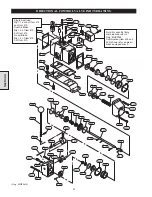

Section 5

Summary of Contents for FA5A

Page 10: ...10 DISC BRAKE PARTS DRAWING Dwg MHP0667 Dwg MHP0630 One Way Clutch Detail Section 1...

Page 19: ...19 Section 2 SERVICE NOTES...

Page 54: ...54 REDUCTION GEAR ASSEMBLY PARTS DRAWING Dwg MHP1221 Section 5...

Page 57: ...57 SERVICE NOTES...

Page 58: ...58 SERVICE NOTES...

Page 59: ...59 SERVICE NOTES...