18

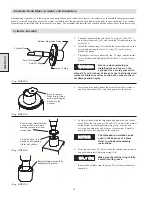

Adjusting the Manual Band Brake

Section 2

1.

Place the band brake handle in a completely released

position. Take up some of the slack in the brake band by

turning the adjustment bolt, and then tighten the locking

capscrew to prevent the adjustment bolt from moving.

2.

Move the control handle towards the engaged position. The

handle should encounter growing resistance starting at

about the last third of its travel. The resistance should not

be enough to stop the handle from going “over-center” at

the end of its travel. Make sure the handle does not contact

the air motor adapter before it goes fully over-center. For

maximum load holding capacity, the handle should just

“over-center” before it touches the motor adapter. If it

“over-centers” too soon, the brake holding capacity will be

diminished. If it does over-center too soon, reposition it on

the splined eccentric shaft and readjust the brake.

3.

The force needed to move the handle “over-center” should be

about 13.5 kg (30 lbs). If the handle cannot go “over-center,”

or if there is excessive resistance, reduce the tension by turning

the adjustment bolt in the counterclockwise direction. There

must be slack in the band brake when the handle is in the

released position. Always test the band brake before use.

Testing the Manual Band Brake

1.

Remove any load from the winch, or if possible remove the

wire rope. If there is wire rope on the winch, this test may

cause it to unspool.

2.

Set the inlet air pressure to 6.3 bar (90 psig) static (while

the air motor is not running).

3.

If the winch is equipped with an automatic disc or band

brake, it must be disengaged before testing the band brake.

Disconnect the air line from the automatic disc or band

brake, and plug it to prevent loss of air pressure. Apply and

hold air pressure from an external source 3.5 to 6.3 bar (50

to 90 psig) directly to the air line fitting on the automatic

disc or band brake while testing the manual band brake.

4.

Move the brake handle towards the winch until it goes fully

“over-center.”

5.

Move the winch control valve handle or operate the pendant

control in the payout direction. The winch drum should not

turn. If it does turn, review the information on troubleshooting

the manual band brake.

Summary of Contents for FA5A

Page 10: ...10 DISC BRAKE PARTS DRAWING Dwg MHP0667 Dwg MHP0630 One Way Clutch Detail Section 1...

Page 19: ...19 Section 2 SERVICE NOTES...

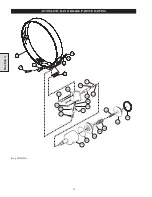

Page 54: ...54 REDUCTION GEAR ASSEMBLY PARTS DRAWING Dwg MHP1221 Section 5...

Page 57: ...57 SERVICE NOTES...

Page 58: ...58 SERVICE NOTES...

Page 59: ...59 SERVICE NOTES...