20

3-3

3-4

4

3

2

1

5

6

INS

TALL

AT

O

R

US

ER

MAINTEN

AN

CE

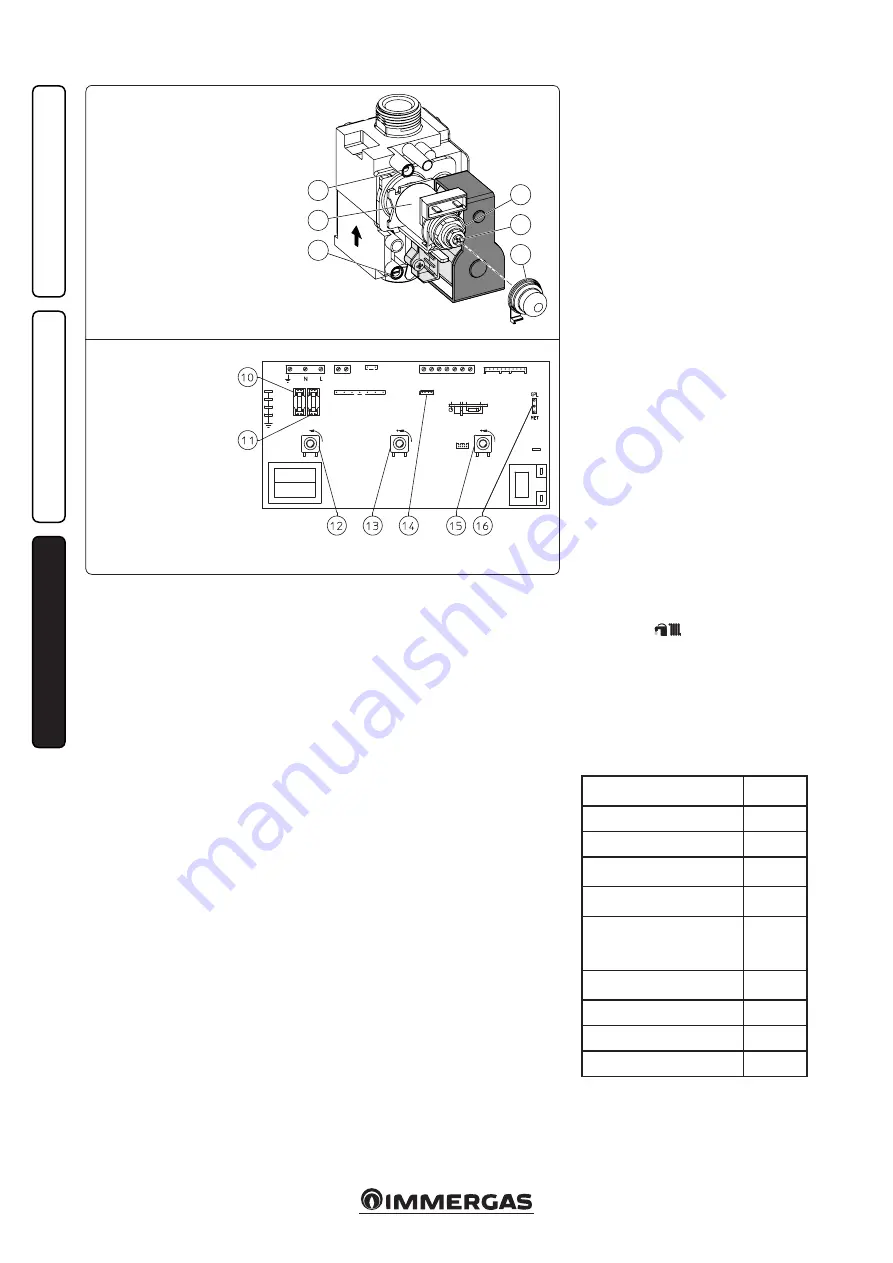

3.4 CONVERTING THE BOILER TO

OTHER TYPES OF GAS.

If the boiler has to be converted to a different gas

type to that specified on the data-plate, request

the relative conversion kit for quick and easy

conversion.

Boiler conversion must be carried out by a

qualified technician (e.g. Immergas Technical

Assistance Service).

To convert to another type of gas the following

operations are required:

- remove the voltage from the appliance;

- replace the main burner injectors, making sure

to insert the special seal rings supplied in the kit,

between the gas manifold and the injectors;

- move jumper 16 (Fig. 3-4) into the correct

position for the type of gas in use (Methane or

L.P.G.);

- to access adjustments on the circuit board the

cover must be removed from the dashboard by

loosening the rear screw fasteners;

- apply voltage to the appliance;

- adjust the boiler maximum heat power;

- adjust the boiler minimum heat power;

- adjust (eventually) the heating power;

- seal the gas flow rate devices (if adjusted);

- after completing conversion, apply the sticker,

present in the conversion kit, near the data-plate.

Using an indelible marker pen, cancel the data

relative to the old type of gas.

These adjustments must be made with reference

to the type of gas used, following that given in the

table (Para. 3.16).

3.5 CHECKS FOLLOWING CONVERSION

TO ANOTHER TYPE OF GAS.

After making sure that conversion was carried out

with a nozzle of suitable diameter for the type of

gas used and the settings are made at the correct

pressure, check that:

- there is no flame return in the combustion

chamber;

- the burner flame is not too high or low and that

it is stable (does not detach from burner);

- the pressure testers used for calibration are

perfectly closed and there are no leaks from the

gas circuit.

N.B.:

All boiler adjustment operations must

be carried out by a qualified technician (e.g.

Immergas Assistance Service). Burner adjustment

must be carried out using a differential “U” or

digital type pressure gauge, connected to the

pressure point located above the sealed chamber

(part. 2 Fig. 1-30) and the gas valve pressure outlet

(part. 4 Fig. 3-3), keeping to the pressure value

given in the tables (Para. 3.16) according to the

type of gas for which the boiler is prepared.

3.6 POSSIBLE ADJUSTMENTS OF THE

GAS VALVE.

• Adjustment of boiler nominal heat output (Fig.

3-3).

- Turn the domestic hot water selector knob (10

Fig. 2-1) to the maximum functioning position;

- open the domestic hot water cock in order to

prevent modulation intervention;

- adjust the boiler nominal power on the brass nut

(3), keeping to the maximum pressure values

stated in the tables (Para. 3.16) depending on

the type of gas;

- by turning in a clockwise direction the heating

potential increases and in an anti-clockwise

direction it decreases.

• Adjust the boiler minimum thermal input (Fig.

3-3).

N.B.:

only proceed after having calibrated the

nominal pressure.

Adjustment of the minimum thermal input is

obtained by operating on the cross plastic screws

(2) on the gas valve maintaining the brass nut

blocked (3);

- disconnect the power supply t the modulating

reel (just disconnect a faston); By turning the

screw in a clockwise direction, the pressure

increases, in an anti-clockwise direction it

decreases. On completion of calibration, re-apply

the power supply tot he modulating reel. The

pressure to which the boiler minimum power

must be adjusted, must not be lower than that

stated in the tables (Para. 3.16) depending on the

type of gas.

N.B.:

to adjust the gas valve, remove the plastic

cap (6); after adjusting, refit the cap and screw.

3.7 PROGRAMMING THE CIRCUIT

BOARD.

The Zeus kW boiler is prepared for possible

programming of several operation parameters.

By modifying these parameters as described

below, the boiler can be adapted according to

specific needs.

To access the programming phase, proceed as

follows: position the main selector switch on

Reset for a period of time between 15 and 20

seconds (after about 10 sec. LEDs 2 and 3 will

start to flash at the same time. Wait for this to

end and re-position the main selector switch on

domestic water and heating). At his point, re-

position the main selector switch on domestic

water-heating (

).

When the programming phase has been activated,

enter the first level where it is possible to choose

the parameter to be set.

The latter is indicated by the fast flashing of one

of the LEDs between 1 and 8 (Fig. 2-1).

Selection is made by turning the domestic hot

water temperature selector switch (10). For

association of the LED to the parameter, see the

following table:

List of parameters

Flashing

LED (fast)

Minimum heating power

LED 1

Maximum heating power

LED 2

Heating switch-on timer

LED 3

Heating power output ramp

LED 4

Heating switch-on delay on request

from Environmental Thermostat,

Digital Remote Control or Remote

Friend Control

V2

LED 5

Domestic water thermostat/Boiler

hysteresis

LED 6

Circulating pump functioning

LED 7

Functioning gas

LED 8

Boiler mode

LEDs1 and 8

Once the parameter to be modified has been

selected, confirm by turning the main selector

switch to Reset momentarily until the LED relative

to the parameter switches-off, then release.

SIT 845 gas valve

Key:

1 - Coil

2 - Minimum power adjustment screws

3 - Maximum power adjustment nut

4 - Gas valve outlet pressure point

5 - Gas valve inlet pressure point

6 - Protection hood

Zeus 24-28 kW circuit board

10 - Line fuse 3.15AF

11 - Neutral fuse 3.15AF

12 - Main selector switch

13 - Domestic water temperature trimmer

14 - RS232 computer interface

15 - Heating temperature trimmer

16 - METHANE L.P.G. gas type selector

Summary of Contents for ZEUS 24 Superior

Page 1: ...ZEUS 24 28 kW IE Instruction booklet and warning 1 038761ENG...

Page 26: ......

Page 27: ......