13

A

B

A

B

1-29

INS

TALL

AT

O

R

US

ER

MAINTEN

AN

CE

1.11 SYSTEM FILLING.

Once the boiler is connected, proceed with system

filling via the filling valve (Fig. 2-2).

Filling is performed at low speed to ensure release

of air bubbles in the water via the boiler and heating

system vents.

The boiler has a built-in automatic venting valve

on the circulator.

Check if the cap is loose.

Open the

radiator air vent valves.

Close vent valves only when water is delivered.

Close the filling valve when the boiler pressure gauge

indicates approx. 1.2 bar.

N.B.

: During these operations, turn on the

circulating pump at intervals by means of the

main selector switch on the control pane.

Vent the

circulation pump by loosening the front cap and

keeping the motor running.

Re-tighten the cap afterwards.

1.12 GAS SYSTEM START-UP.

To start up the system proceed as follows:

- open windows and doors;

- avoid presence of sparks or naked flames;

- bleed all air from pipelines;

- check that the internal system is properly sealed

according to specifications.

1.13 BOILER START-UP (LIGHTING).

For issue of the Declaration of Conformity provided

for by Italian Law, the following must be performed

for boiler start-up:

- check that the internal system is properly sealed

according to specifications;

- ensure that the type of gas used corresponds to

boiler settings;

- switch on the boiler and ensure correct ignition;

- make sure that the gas flow rate and relevant

pressure values comply withthose given in the

manual (Para. 3.16);

- ensure that the safety device is engaged in the event

of gas supply failureand check activation time;

- check activation of the main circuit-breaker

selector upstream from theboiler and on the unit;

- check that the concentric intake/exhaust terminal

(if fitted) is not blocked.

The boiler must not be started up in the event of

failure to comply with any of the above.

N.B.:

The boiler preliminary check must be carried

out by a qualified technician. The boiler warranty is

valid as of the date of testing. The test certificate and

warranty is issued to the user.

1.14 DOMESTIC HOT WATER BOILER

DEVICE.

The Zeus kW boiler is the accumulation type with

a capacity of 45 litres. It contains a large coiled

stainless steel heat exchanger pipe, which allows to

notably reduce hot water production times. These

boilers built with stainless steel casing and bottoms,

guarantee long duration. The assembly concepts and

welding (T.I.G.) are implemented to the minimum

detail to ensure maximum reliability.

The lower inspection flange ensures practical control

of the boiler and the coiled heat exchanger and easy

internal cleaning. The domestic water attachments

are found on the flange cover (cold inlet and hot

outlet) and also the magnesium anode holder cap,

including the latter, supplied as standard for internal

protection of the boiler from possible corrosion.

N.B.:

every year a skilled technician (e.g. Immergas

Authorised After-sales Service), must check the

efficiency of the boiler’s Magnesium Anode. The

boiler is prepared for introduction of the domestic

water re-circulation connection.

1.15 CIRCULATION PUMP.

Zeus kW Range boilers are supplied with a built-in

circulation pump with 3-position electric speed

control. The boiler does not operate correctly with

the circulation pump on first speed. To ensure op-

timal boiler operation, in the case of new systems

(single pipe and module) it is recommended to

use the circulation pump at maximum speed. The

circulation pump is already fitted with a capacitor.

Pump release.

If, after a prolonged period of inac-

tivity, the circulation pump is blocked, unscrew the

front cap and turn the motor shaft using a screwdri-

ver. Take great care during this operation to avoid

damage to the motor.

1.16 KITS AVAILABLE ON REQUEST.

• Kit of system shutoff valves (on request). The

boiler is designed for installation of system shutoff

valves to be placed on delivery and return pipes

of the connection assembly. This kit is particularly

useful for maintenance as it allows the boiler to be

drained separately without having to empty the

entire system.

• System zone Kit (on request). If the heating system

is to be divided into several zones (max. three), in

order to interlock them with separate adjustments

and to keep water flow rate high for each zone,

Immergas supplies zone system kits by request.

• Polyphosphate batching kit (on request). The

polyphosphate dispenser Reduces the formation

of lime-scale and preserves the original heat

exchange and domestic hot production water

conditions. The boiler is prepared for application

of the polyphosphate dispenser kit.

The above kits are supplied complete with instruc-

tions for assembly and use.

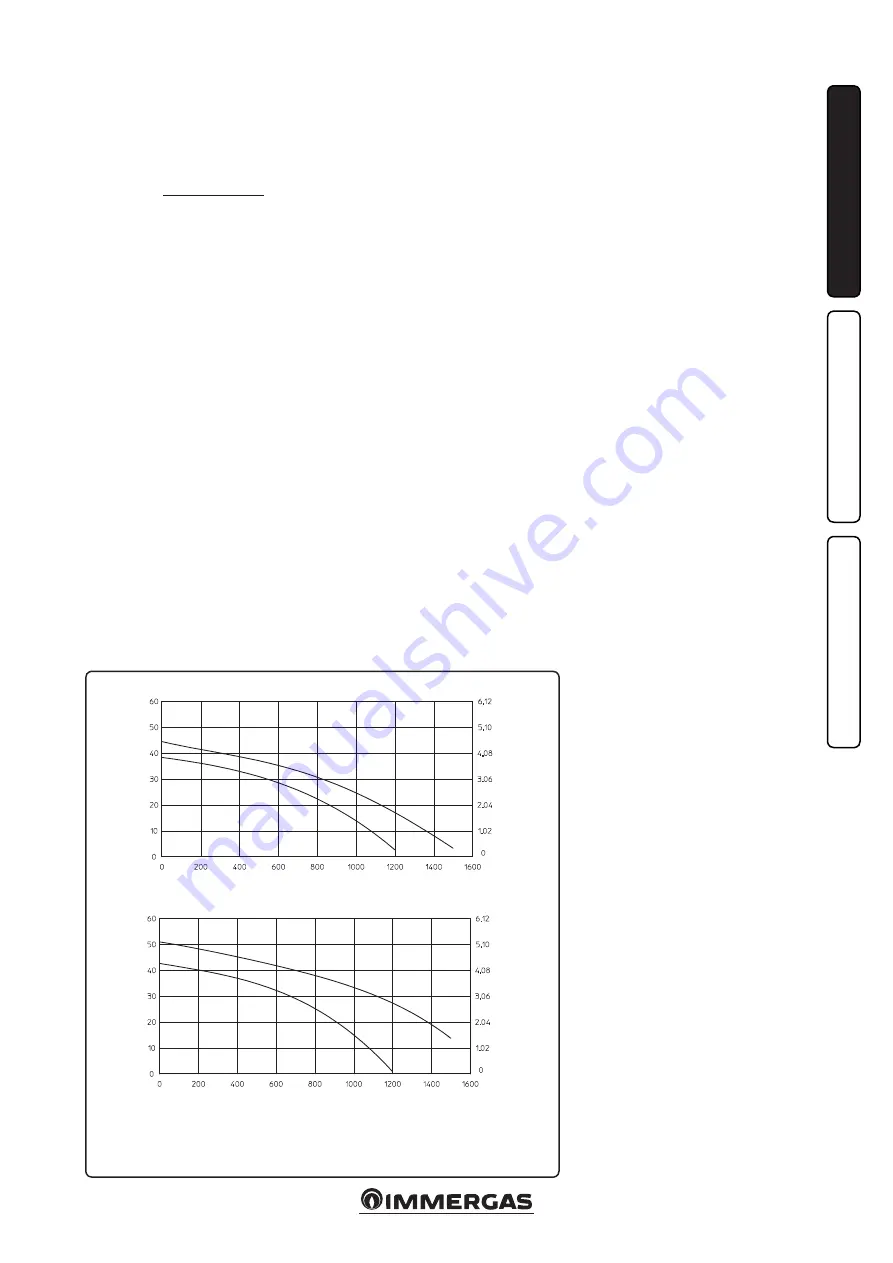

A = Total head available to the plant on the third speed (screws tightened by 1.5 revs with

respect to the completely loose adjustment screws)

B = Total head available to the plant on the second speed (screws tightened by 1.5 revs

with respect to the completely loose adjustment screws).

Total head available to the plant.

To

ta

l h

ea

d (m H

2

O)

Capacity (l/h)

To

ta

l h

ea

d (kP

a)

Zeus 24 kW

Zeus 28 kW

To

ta

l h

ea

d (m H

2

O)

Capacity (l/h)

To

ta

l h

ea

d (kP

a)

Summary of Contents for ZEUS 24 Superior

Page 1: ...ZEUS 24 28 kW IE Instruction booklet and warning 1 038761ENG...

Page 26: ......

Page 27: ......