The information contained in this document is the property of Automatic Systems and is confidential. The recipient shall refrain from using it for any purpose other than the use of the products or the

execution of the project to which it refers, and from communicating it to third parties without Automatic Systems’ prior written agreement. Document subject to change without notice.

BL3x-MT-EN-08

page

43/59

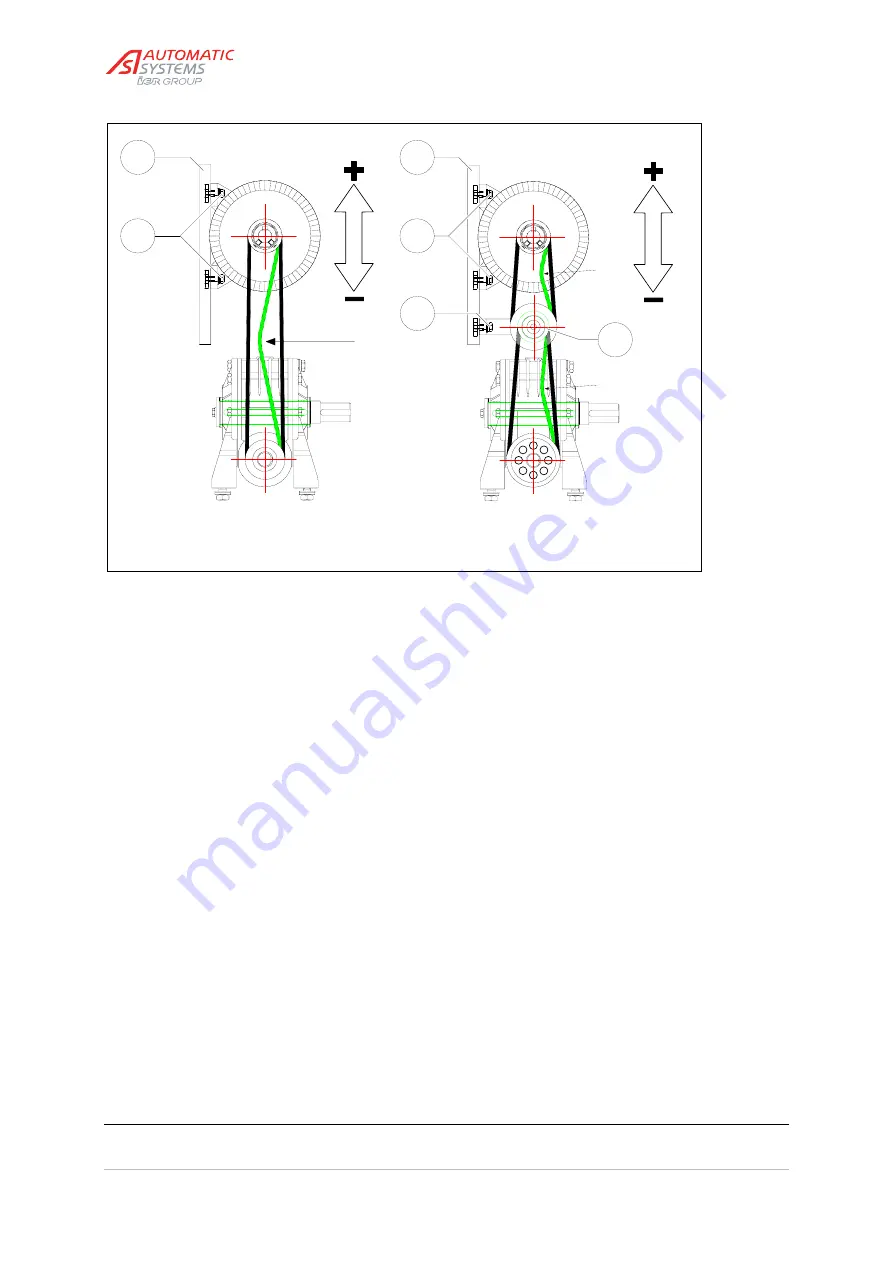

Fig. 25a

10mm

25:1

25:2

6mm

Fig. 25b

6mm

25:5

25:6

25:4

25:3

6.2.1. Single belt (Fig. 25a)

--

Loosen slightly the four screws (

25:1

) that fix the motor.

--

If required, slide the motor downwards in its guides (

25:2

), remove the old V-belt and fix the new

one. Refer to page 040 of the "

BL3x Spare parts

" to know the exact reference of the belt to use

depending on the barrier specifications.

--

Slide the motor upwards in its guides. The tension is properly adjusted if the belt can be depressed

about 10mm when you push on it as illustrated in Fig. 25a.

--

Make sure that the motor is horizontal.

--

Tighten the four screws (

25:1

) firmly again.

6.2.2. Double belt (Fig. 25b)

--

Loosen slightly the four screws (

25:3

) that fix the motor.

--

Slide the motor a few centimetres downwards in its guides (

25:4

) and tighten the screws (

25:3

)

again temporarily.

--

Loosen slightly the two screws (

25:5

) that fix the intermediate pulley (

25:6

).

--

If required, slide the intermediate pulley (

25:6

) downwards in its guides (

25:4

), remove the old

gearbox pulley and fix the new one.

--

Slide the intermediate pulley upwards in its guides. The tension is properly adjusted if the belt can

be depressed about 6mm when you push on it as illustrated in Fig. 25b.

--

Tighten the two screws (

25:5

) firmly again.

--

If required, remove the old motor belt and fix the new one. Refer to page 040 of the "

BL3x Spare

parts

" to know the exact reference of the belts to use depending on the barrier specifications.

--

Slide the motor upwards in its guides. The tension is properly adjusted if the belt can be depressed

about 6mm when you push on it as illustrated in Fig. 25b.

--

Make sure that the motor is horizontal.

--

Tighten the four screws (

25:3

) firmly again.

Reminder

: In case a closing or opening movement is reversed, the belt(s) must not absorb the inertia

of the mechanism!

6.3.

Safety torque limiter adjustment