56

Response FF80

- Installation

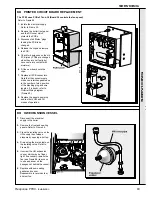

86 Flame detection and mixture

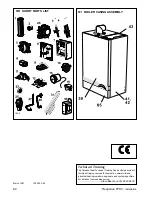

Note.

When panels are removed for service, live parts are exposed so caution should be exercised when fault-finding.

FAULT FINDING

Foot Note:

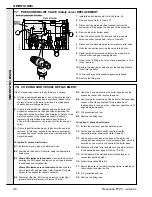

POLARITY CHECKS

Use a multimeter (set to measure 230 V AC or more), connecting the black lead to a reliable

Earth

point (

not Neutral for this

particular test)

.

You should find 230 V on terminal L and zero (or a small reading) on terminal N.

N.B.

Some meters may trip residual current devices during this test.

Remove the fan.

Is the detection lead undamaged and attached

to the (single) detection electrode terminal at

the rear of the burner base ?

Check detection lead for continuity.

Check that the electrode is in the flame area

and within 12mm (± 1mm) of the burner at

closest point.

Rectify any fault.

Does the boiler now run ?

YES

Is this a new installation ?

Has any electrical work been done to the boiler

or the house wiring ?

YES

Check the polarity of the incoming mains to

the boiler (see footnote).

Is this correct ?

YES

Check the polarity of the mains input

to

PCB 37

when the fan starts.

Is this correct ?

Does the boiler now run ?

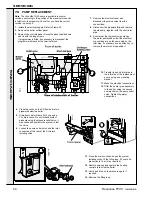

Remove the burner assembly.

Check the detection electrode visually for

damage / contamination / moisture.

If possible, check insulation resistance between

the electrode and earth with the lead

disconnected - this should be at least 100

Megohms.

Is it OK ?

NO

NO

YES

YES

NO

Check all connections on PCB 37.

Check for moisture on PCB 37.

If no fault found, check PCB 37 by substitution.

YES

EXIT

YES

YES

YES

NO

F

AUL

T FINDING

Boiler does not light, or lights briefly

at the

correct

burner pressure then

goes off, leaving LED 2 on PCB 37 lit

Check that the gas injector is of the correct size

(see Data Plate) and is unobstructed.

Is this correct ?