23

Response FF80

- Installation

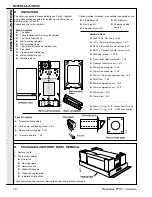

INSTALLATION

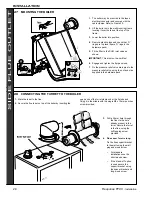

SIDE FLUE OUTLET

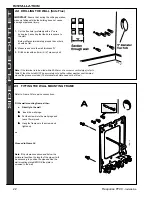

24 FITTING THE WALL MOUNTING FRAME - continued

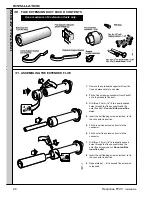

25 CUTTING THE FLUE TO LENGTH

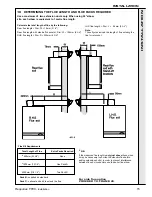

1.

The flue cut length is calculated as detailed in

Frame 10.

2.

Measure from the groove and mark the tube.

3.

To ensure the tube is cut square, mark the

flue all the way round, using, e.g. a long

straight strip of paper with its ends

overlapped.

4.

Cut to length, using the cardboard support

aid.

5.

Remove the cardboard support and any

burrs.

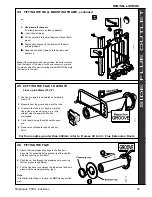

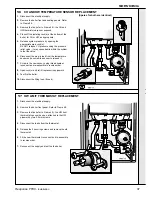

26 FITTING THE FLUE

For flue lengths greater than 600mm refer to Frames 30 to 32 - Flue Extension Ducts

or

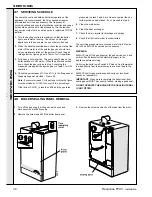

b. Use stand-off channels

(To allow pipework to be taken upwards).

z

z

z

z

z

Insert the wall plugs.

z

z

z

z

z

Put the screws into the wall plugs and leave 10mm

proud.

z

z

z

z

z

Fasten each channel to the frame with the 6mm

screws provided.

z

z

z

z

z

Hang channels and frame onto the screws and

tighten up.

Note.

If the clearances above and below the boiler are less

than the length of the pipes it will be necessary to position

the pipes behind the wall mounting plate BEFORE the plate

is screwed to the wall.

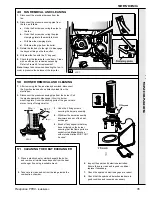

Flues up to 600mm (23

5/8

")

1.

Attach the clamping/sealing rings to the flue (this

prevents the assembly being pushed right through the

hole and causing an accident).

2.

Pass the cut flue through the prepared hole, ensuring

that the groove is uppermost.

3.

Pull the flue back to compress the rubber seal and fix in

place with the clamping/sealing rings.

Note.

To facilitate turret fixing or removal do

NOT

make good the

wall.