54

Response FF80

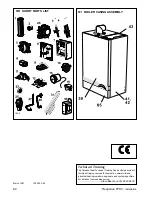

- Installation

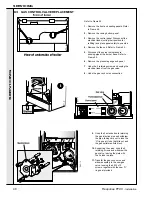

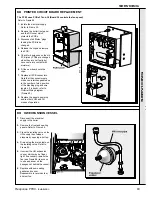

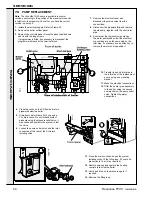

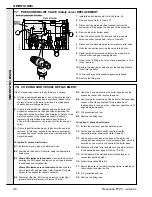

84 Power to PCB 37 but burner pressure incorrect or zero

NO

Clear the blockage and take steps to

prevent recurrence

NO

Are air and flue ducts free from blockage ?

Check all items connected to PCB 37

for short circuits between Live and

Neutral, also between Live and Earth.

If none found, reconnect one by one

(gas valve last) until the faulty item is

found.

If no fault found or fuse blows with no

items connected, check PCB 37 by

substitution.

Is the appliance gas cock fully open ?

NO

NO

Is the gas supply pressure adequate at the

appliance inlet during an ignition trial period

(i.e. when LED 2 on PCB 37 goes off) ?

NO

YES

Contact the

gas

supplier

Is the supply pressure correct at the

gas meter ?

Rectify the fault and take steps to

prevent recurrence

NO

Are the fan and burner pressure sensing

pipes correctly connected, free from

damage and unobstructed by solid matter

or moisture ?

Is there Live on the brown lead of the gas

valve connector on PCB 37

during an

ignition trial period

?

Are both connectors correctly fitted to the

gas valve, with screws secured

but not

overtightened ?

Remove connectors. With mains OFF,

check continuity of leads from each socket

unit back to the corresponding terminals in

the control box. Are leads in good order ?

Check gas valve by substitution

Change lead assembly

Return

to main

menu

YES

YES

YES

YES

YES

YES

YES

YES

NO

Notes.

1.

The burner pressure is not user-adjustable: it is regulated by the gas valve, according to the air flow generated by the fan and, on

cold ignition, should be slightly higher than the value quoted on the Data Plate. Long flues will cause a slightly lower burner

pressure than standard flues.

2.

Equilibrium fan differential pressures should be as detailed in Frame 45.

Determine the cause of

pressure loss (e.g. supply

pipe too small ?) and rectify

Check PCB 37 by substitution

FAULT FINDING

Is the fuse good on PCB 37 ?

(LED3 lit confirms this

F

AUL

T FINDING