10

Response FF80

- Installation

GENERAL

Ancillary pipework not forming part of the useful heating surface

should be lagged to prevent heat loss and any possible freezing

- particularly where pipes run through roof spaces or ventilated

underfloor spaces.

Draining taps should be at least

1/2

" BSP nominal size and be in

accordance with BS 2879.

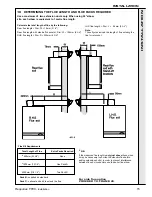

Maximum recommended system hydraulic losses are given in

Table 7, within Frame 5.

WATER TREATMENT

Antifreeze fluid, corrosion and scale inhibitor fluids suitable for

use with boilers having copper heat exchangers may be used in

the central heating system.

For further information contact either:

Fernox Manufacturing Co. Ltd.

Britannic Works

Clavering

Essex

CB11 4QZ

Tel.01799 550811

or

Grace Service Chemicals

Grace Dearborn Ltd.,

Widnes

Cheshire

Tel. 0151 424 5351

THERMOSTATIC RADIATOR VALVES (TRV)

Caradon Ideal Ltd.

recommend that heating systems utilising

full thermostatic radiator valve control of temperature in

individual rooms should also be fitted with a room thermostat

controlling the temperature in a space served by radiators not

fitted with such a valve as stated in BS. 5449.

When thermostatic radiator valves are used, the space heating

temperature control over a living area having a heating

requirement of at least 10% of the boiler heat output should be

achieved using a room thermostat whilst other rooms are

individually controlled by thermostatic radiator valves.

For further information refer to the 'Good Practice Guide 143' , a

publication of the Energy Efficiency Office, available from the

Building Research Establishment, Garston, Watford WD2 7JR.

Tel: 01923 664258.

ELECTRICAL SUPPLY

Wiring external to the appliance MUST be in accordance with

the current I.E.E. (BS.7671) Wiring Regulations and any local

regulations which apply.

The point of connection to the mains should be readily

accessible and adjacent to the boiler, except for bathroom

installations where the point of connection to the mains MUST

be situated outside of the bathroom.

Note

.

Where a room sealed appliance is installed in a room

containing a bath or shower then the appliance and any

electrical switch or appliance control utilising mains electricity

should be so situated that it cannot be touched by a person

using the bath or shower.

REQUIREMENTS

1. General

Any method of filling, refilling, topping up or flushing sealed

primary hot water circuits from the mains via a temporary

hose connection is only allowed if it complies with Water

Bye-law 14, which states:

" (1) No closed circuit shall be connected to a supply pipe.

(2) Paragraph (1) shall not apply to a temporary connection

provided that:

a. The connection is made through a double check valve

assembly or some other no less effective device which is

permanently connected to that circuit;

and

b. The temporary connection is removed after use. "

The method described in this instruction complies with that

Byelaw.

2. BS. Requirements

The installation must comply with the requirements of

BS. 6891:1988 and BS. 5449.

3. Flow Temperature

The installation should be designed to work with flow

temperatures of up to 90° C.

4. Working Pressure

All components of the system must be suitable for a

working pressure of 3 bar (45 lb/in

2

) and temperature of

110°C. Extra care should be taken in making all

connections so that the risk of leakage is minimised.

The following components are incorporated within the

appliance:

a.

Circulating pump.

b.

Safety valve; with a non-adjustable pre-set lift pressure

of 3 bar (45lb/in

2

).

c.

Pressure gauge; covering a range of 0-6 bar.

d.

8-litre expansion vessel; with an initial charge pressure

of 1 bar (15 lb/in

2

).

e.

Domestic hot water (DHW) mini expansion vessel.

For further details refer to BS.5449:1 and the British Gas

Corporation publication 'Specifications for Domestic Central

Heating and Hot Water'.

3

SEALED SYSTEM REQUIREMENTS - Central Heating

N.B. Ideal Response FF80

combination boilers are suitable for

fully pumped pressurised sealed systems only.