2

HEM

TM

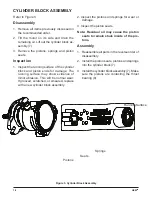

The cylinder block pistons in the HEM motor

are set at a fixed displacement by a swash

plate angle. As pressurized fluid from the pump

pushes against the cylinder block pistons, they

are forced to rotate with the thrust bearing. As

the pistons rotate with the thrust bearing, they

create torque and rotary motion that that is

transmitted to the motor shaft. Torque contin-

ues to develop as long as the piston is being

pushed out of the cylinder block. When the

piston reaches the end of it’s movement out of

the cylinder block, it gets pushed back into the

cylinder and fluid inside the piston is discharged

through the low pressure port of the motor.

Pistons develop torque only through half of the

cylinder block rotation cycle. Therefore, multiple

pistons are used to provide a constant and con-

tinuous torque to the motor shaft. Reversing the

direction of the incoming pressurized fluid into

the motor reverses the direction of the motor

output rotation.

INTRODUCTION

The purpose of this manual is to provide in-

formation useful in servicing the Hydro-Gear

®

HEM

TM

High Efficiency Motor. This manual

includes general descriptions, technical

specifications, servicing and troubleshooting

procedures.

Should the motor require servicing, the exterior

of the motor will need to be thoroughly cleaned

before beginning most procedures. Do not wash

the motor while it is hot.

It is best to not al-

low direct spray from a pressure washer to

clean the motor.

GENERAL DESCRIPTION

The HEM is a fixed displacement axial piston

motor. The fixed displacement motor design,

allows an output speed range between zero and

maximum speed in both forward and reverse.

Each high speed / low torque motor has a rotat-

ing kit utilizing spherical-nosed axial pistons for

the transfer and control of power.

DESCRIPTION AND OPERATION

Summary of Contents for HGM-H Series

Page 1: ...BLN 0043 January 2018 HGM H Series Motor Service and Repair Manual ...

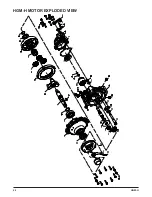

Page 25: ...24 HGM H HGM H MOTOR EXPLODED VIEW ...

Page 29: ...HEMTM Series Motor Service and Repair Manual BLN 0083 January 2018 ...

Page 52: ...PRM MOTOR Service and Repair Manual ...

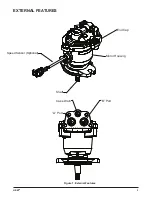

Page 56: ...PRM 3 EXTERNAL FEATURES PRM MOTOR Figure 1 PRM External Features ...

Page 77: ...24 PRM SECTION 8 PARTS LIST Figure 48 MA04K030 ...

Page 81: ...BLN 50231 January 2018 BDP 10L PL Hydrostatic Pump Service and Repair Manual ...

Page 82: ......

Page 83: ......

Page 84: ......

Page 85: ......

Page 86: ......

Page 87: ......

Page 88: ......

Page 89: ......

Page 90: ......

Page 91: ......

Page 92: ......

Page 95: ......

Page 96: ......

Page 97: ......

Page 98: ......

Page 99: ......

Page 100: ...HGM 12P LSHT Wheel Motor Service and Repair Manual BLN 52197 January 2018 ...

Page 102: ...2 Exploded view HGM P ...

Page 117: ...HGM E LSHT Wheel Motor Service and Repair Manual BLN 52198 January 2018 ...

Page 144: ...2 P Series EXTERNAL FEATURES PC SERIES Figure 1 PC Pump with Standard Charge Pump ...

Page 146: ...4 P Series EXTERNAL FEATURES PJ SERIES Figure 3 PJ Pump with Standard Charge Pump ...

Page 147: ...5 P Series Figure 4 PK Pump With Standard Charge Pump EXTERNAL FEATURES PK SERIES ...

Page 176: ...34 PC Series Figure 16 PC Pump BOXES INDICATE ITEMS INCLUDED IN Kit Number ...

Page 192: ...52 PG PE Series Figure 17 PG PE Pump BOXES INDICATE ITEMS INCLUDED IN KITS Kit Number ...

Page 208: ...70 PJ Series Figure 17 PJ Pump BOXES INDICATE ITEMS INCLUDED IN Kit Number ...

Page 224: ...88 PK Series Figure 17 PK Pump BOXES INDICATE ITEMS INCLUDED IN Kit Number ...

Page 240: ...106 PR Series Figure 17 PR Pump BOXES INDICATE ITEMS INCLUDED IN KITS Kit Number ...

Page 261: ...HGM C LSHT Wheel Motor Service and Repair Manual BLN 52690 January 2018 ...