19

P Series

FLUID VOLUME AND LEVEL

Certain situations may require additional fluid to

be added or even replaced. Refer to the vehicle

manufacturer’s recommendations for the proper fill

location and level. After maintenance or oil change,

follow purging procedures below and check the

fluid level once the unit has been operated for ap

-

proximately 1 minute.

FLUID CHANGE

In the event of oil contamination or degradation,

oil addition or change may alleviate certain per-

formance problems. Refer to the vehicle manufac-

turer’s recommended oil change frequency. Refer to

purging procedures below after changing fluids.

FILTERS

An inlet filter is required to insure that only clean fluid

enters the system. Refer to the vehicle manufacture

for approved filter replacement.

PURGING PROCEDURES

Due to the effects air has on efficiency in hydrostatic

drive applications, it is critical that air is removed or

purged from the system.

These purge procedures must be preformed any-

time a hydrostatic system has been opened for

maintenance or repair, or if any additional oil has

been added to the system.

Air creates inefficiency because it has compres

-

sion and expansion rates that are higher than that

of oil.

Air trapped in the oil may cause the following

symptoms:

1. Noisy operation.

2. Lack of power or drive after short-term

operation.

3. High operation temperature and excessive

expansion of oil.

Before starting, make sure the reservoir is at the

proper oil level. If it is not, fill to the vehicle manu

-

facturer’s specifications.

The following procedures should be performed

with the vehicle drive wheels off the ground, then

repeated under normal operating conditions.

WARNING

POTENTIAL FOR SERIOUS INJURY

Certain procedures require the vehicle

engine to be operated and the vehicle to

be raised off of the ground. To prevent

possible injury to the servicing techni-

cian and/or bystanders, insure the ve-

hicle is properly secured.

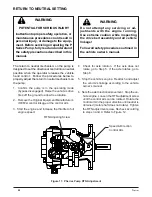

1. With the bypass valve open and the engine

running, slowly move the directional control

in both forward and reverse directions (5 to 6

times). As air is purged from the unit, the oil level

in the reservoir will drop.

2. With the bypass valve closed and the engine

running, slowly move the directional control

in both forward and reverse directions (5 to

6 times). Check the oil level, and add oil as

required after stopping engine.

3. It may be necessary to repeat steps 1 and

2 until all the air is completely purged from

the system. When the P Series Pump moves

forward and reverse at normal speed and the

reservoir oil remains at a constant level, purging

is complete.

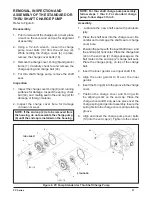

Cleanliness is a key factor in the successful repair of

pumps. Thoroughly clean all exposed surfaces prior

to any type of maintenance. Cleaning of all parts

by using a solvent wash and air drying is usually

adequate. As with any precision equipment, all parts

must be kept free of foreign material and chemicals.

Protect all exposed sealing areas and open cavities

from damage and foreign material.

Upon removal, all seals, O-rings, and gaskets

should be replaced. During installation, lightly lu-

bricate all seals, O-rings, and gaskets with clean

petroleum jelly prior to assembly. Also protect the

inner diameter of seals by covering the shaft ma-

chined features with plastic wrap or equivalent.

Note: “Any and all Hydro-Gear com-

ponents removed and replaced during

service are recyclable.”

Summary of Contents for HGM-H Series

Page 1: ...BLN 0043 January 2018 HGM H Series Motor Service and Repair Manual ...

Page 25: ...24 HGM H HGM H MOTOR EXPLODED VIEW ...

Page 29: ...HEMTM Series Motor Service and Repair Manual BLN 0083 January 2018 ...

Page 52: ...PRM MOTOR Service and Repair Manual ...

Page 56: ...PRM 3 EXTERNAL FEATURES PRM MOTOR Figure 1 PRM External Features ...

Page 77: ...24 PRM SECTION 8 PARTS LIST Figure 48 MA04K030 ...

Page 81: ...BLN 50231 January 2018 BDP 10L PL Hydrostatic Pump Service and Repair Manual ...

Page 82: ......

Page 83: ......

Page 84: ......

Page 85: ......

Page 86: ......

Page 87: ......

Page 88: ......

Page 89: ......

Page 90: ......

Page 91: ......

Page 92: ......

Page 95: ......

Page 96: ......

Page 97: ......

Page 98: ......

Page 99: ......

Page 100: ...HGM 12P LSHT Wheel Motor Service and Repair Manual BLN 52197 January 2018 ...

Page 102: ...2 Exploded view HGM P ...

Page 117: ...HGM E LSHT Wheel Motor Service and Repair Manual BLN 52198 January 2018 ...

Page 144: ...2 P Series EXTERNAL FEATURES PC SERIES Figure 1 PC Pump with Standard Charge Pump ...

Page 146: ...4 P Series EXTERNAL FEATURES PJ SERIES Figure 3 PJ Pump with Standard Charge Pump ...

Page 147: ...5 P Series Figure 4 PK Pump With Standard Charge Pump EXTERNAL FEATURES PK SERIES ...

Page 176: ...34 PC Series Figure 16 PC Pump BOXES INDICATE ITEMS INCLUDED IN Kit Number ...

Page 192: ...52 PG PE Series Figure 17 PG PE Pump BOXES INDICATE ITEMS INCLUDED IN KITS Kit Number ...

Page 208: ...70 PJ Series Figure 17 PJ Pump BOXES INDICATE ITEMS INCLUDED IN Kit Number ...

Page 224: ...88 PK Series Figure 17 PK Pump BOXES INDICATE ITEMS INCLUDED IN Kit Number ...

Page 240: ...106 PR Series Figure 17 PR Pump BOXES INDICATE ITEMS INCLUDED IN KITS Kit Number ...

Page 261: ...HGM C LSHT Wheel Motor Service and Repair Manual BLN 52690 January 2018 ...