117

PW / PY Series

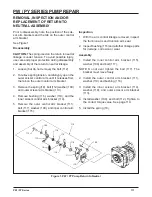

Refer to Figure 10.

Disassembly

1. Prior to removal of the auxiliary pump, place a

mark on the auxiliary pump, charge pump (41)

and end cap (25) for alignment at assembly.

2. Use a 10mm wrench to loosen the auxiliary

pump bolts (56) from the end cap (25). While

holding the auxiliary pump in place, remove the

bolts (56).

3. Remove the auxiliary pump, gasket, O-ring (39)

and charge pump (41). While removing the

charge pump, be sure to retain the spring and

ball (44A) housed in the end cap (25).

4. Remove the plug (66) from the filter cover

(67).

5. Use a 7/8 inch wrench to remove the filter cover

assembly (67) from the pump.

6. Remove the O-ring and filter (54).

7. Remove the charge relief valve assembly (44)

and auxiliary relief valve assembly (45) from the

auxiliary pump.

Inspection

1. With the auxiliary pump removed, inspect the

pump running surfaces for wear or damage.

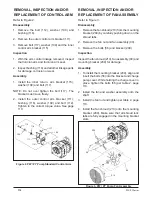

REMOVAL, INSPECTION AND/OR

REPLACEMENT OF AUXILIARY

PUMP (IF EQUIPPED)

Figure 10. PW / PY Series Auxiliary Pump

2. Inspect all O-rings, gasket and mounting

seats.

3. Inspect the filter cover assembly threads and

filter for wear, damage or foreign material.

Assembly

1. Install the check ball, spring, and cap as one

assembly (45) into the auxiliary relief valve port.

Tighten to the correct torque value. See page

110.

2. Install the poppet, spring and cap as one

assembly (44) into the charge relief port. Tighten

to the correct torque value. See page 110.

3. Install the filter (54) and O-ring into the filter

cover assembly (67). Install the assembly (67)

into the auxiliary pump and tighten. Install the

plug (66) into the filter cover (67).

4. Lay the PW pump (input shaft down), so the end

cap is horizontal. Install the O-ring (39) into the

charge pump (41).

5. Install the gasket onto the auxiliary pump.

6. Make sure that the ball and spring (44A) are

seated in the end cap (25), then position the

auxiliary pump and gasket with the aligning mark

on the charge pump (7). Insure that the pump

fully engages the alignment pins (69).

7. Align and insert the bolts (56) into the auxiliary

pump. While holding the auxiliary pump and

charge pump in place, tighten the bolts (56) per

table 2, page 110.

45

168

66

67

54

(2X) 56

44

40

69

39

41

39

44A

1

25

Summary of Contents for HGM-H Series

Page 1: ...BLN 0043 January 2018 HGM H Series Motor Service and Repair Manual ...

Page 25: ...24 HGM H HGM H MOTOR EXPLODED VIEW ...

Page 29: ...HEMTM Series Motor Service and Repair Manual BLN 0083 January 2018 ...

Page 52: ...PRM MOTOR Service and Repair Manual ...

Page 56: ...PRM 3 EXTERNAL FEATURES PRM MOTOR Figure 1 PRM External Features ...

Page 77: ...24 PRM SECTION 8 PARTS LIST Figure 48 MA04K030 ...

Page 81: ...BLN 50231 January 2018 BDP 10L PL Hydrostatic Pump Service and Repair Manual ...

Page 82: ......

Page 83: ......

Page 84: ......

Page 85: ......

Page 86: ......

Page 87: ......

Page 88: ......

Page 89: ......

Page 90: ......

Page 91: ......

Page 92: ......

Page 95: ......

Page 96: ......

Page 97: ......

Page 98: ......

Page 99: ......

Page 100: ...HGM 12P LSHT Wheel Motor Service and Repair Manual BLN 52197 January 2018 ...

Page 102: ...2 Exploded view HGM P ...

Page 117: ...HGM E LSHT Wheel Motor Service and Repair Manual BLN 52198 January 2018 ...

Page 144: ...2 P Series EXTERNAL FEATURES PC SERIES Figure 1 PC Pump with Standard Charge Pump ...

Page 146: ...4 P Series EXTERNAL FEATURES PJ SERIES Figure 3 PJ Pump with Standard Charge Pump ...

Page 147: ...5 P Series Figure 4 PK Pump With Standard Charge Pump EXTERNAL FEATURES PK SERIES ...

Page 176: ...34 PC Series Figure 16 PC Pump BOXES INDICATE ITEMS INCLUDED IN Kit Number ...

Page 192: ...52 PG PE Series Figure 17 PG PE Pump BOXES INDICATE ITEMS INCLUDED IN KITS Kit Number ...

Page 208: ...70 PJ Series Figure 17 PJ Pump BOXES INDICATE ITEMS INCLUDED IN Kit Number ...

Page 224: ...88 PK Series Figure 17 PK Pump BOXES INDICATE ITEMS INCLUDED IN Kit Number ...

Page 240: ...106 PR Series Figure 17 PR Pump BOXES INDICATE ITEMS INCLUDED IN KITS Kit Number ...

Page 261: ...HGM C LSHT Wheel Motor Service and Repair Manual BLN 52690 January 2018 ...