FCU 8000 series

Performing maintenance

HYDAC FILTER SYSTEMS GMBH

en(us)

Page 94/112

BEWA FCU8000 3109776d en-us 2011-06-10.doc

2011-06-10

Performing maintenance

Carry out the specified configuration, maintenance and inspection work every six

months or, at the latest, when an error message or malfunction makes it necessary.

Disconnect the FCU from the power supply when performing any maintenance,

inspection or repair work.

Once maintenance work is complete, check that the FCU is still working properly.

Cleaning the FCU

Clean the control panel with a clean, moist cloth. Do not use any chemical cleaning

agents, as these may damage the film attached to the surface of the FCU. Clean the

outside of the FCU with a moist cloth.

Changing the FCU Filter Element

The FCU has an internal filter element with a differential pressure switch. The

differential pressure switch switches at 2 bar. The message "Filter clogged" will

appear on the display. Ensure that the flow rate control valve is not closed.

If the filter is contaminated, but the differential pressure of 2 bar cannot be achieved

(e.g. with an inlet pressure <2 bar), then there will be no indication on the display.

Only the message "Flow error" will appear in such cases.

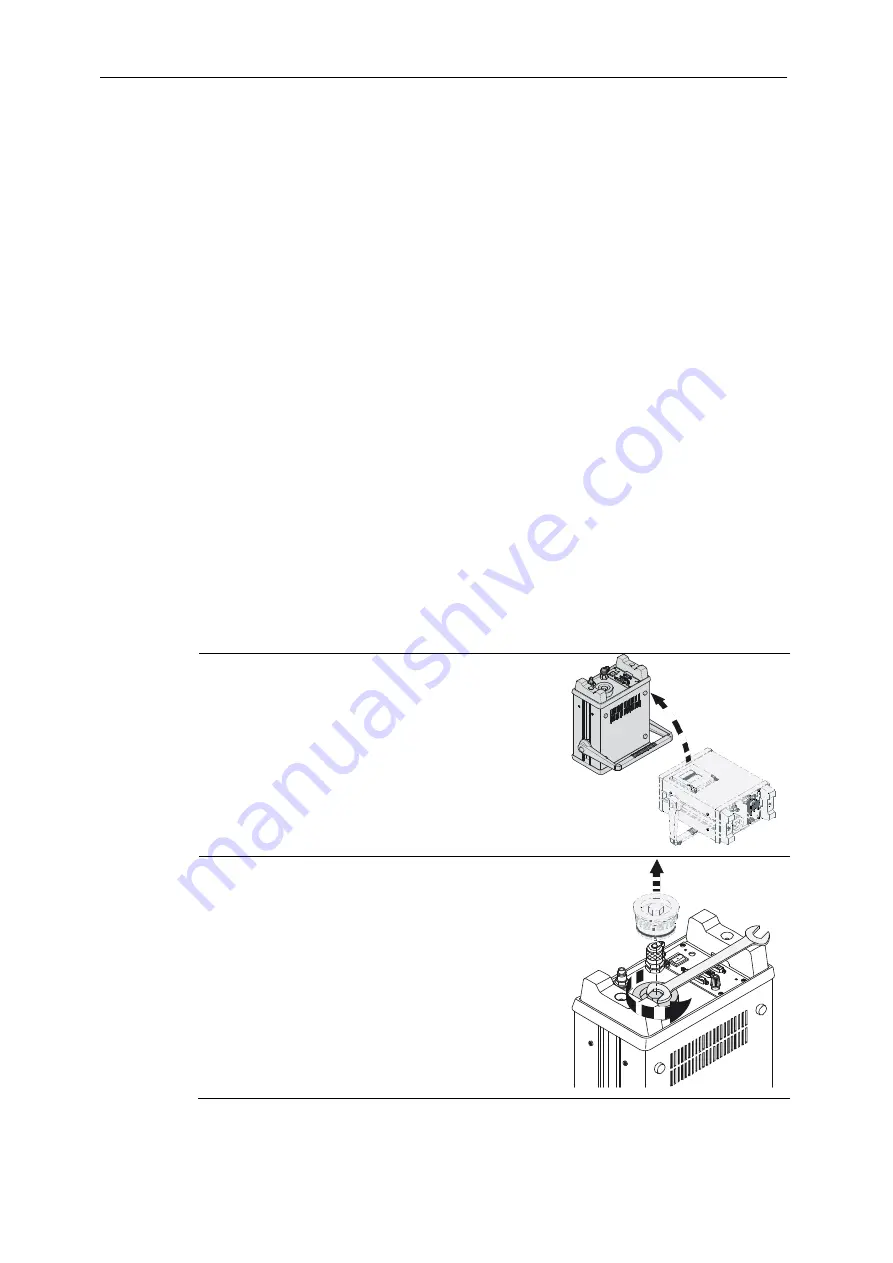

To change the filter, proceed as follows:

1. Put a suitable drip tray in place to catch the oil

(~0.5 l).

Turn the FCU so that the rear side faces

upwards. Ensure that the flow rate control

valve is not damaged.

2. Unscrew the screw plug with a size 19 ring

spanner by turning it counterclockwise.