72

B 215 / B 225 Evo

Operator’s manual

plus the maximum load allowed. The support base on the floor and the envisaged fixing

means must also be taken into account.

Environmental operating conditions must comply with the following requirements:

- relative humidity ranging from 30% to 80% (without condensation);

- temperature ranging from 0° to +50°C.

WARNING

For information concerning the technical features, warnings and maintenance instructions

consult the related operator manuals provided with the documentation of the machine.

CAUTION

The machine must not be operated in potentially explosive atmospheres.

The machine is supplied partially disassembled and is to be assembled according to the

procedures described below.

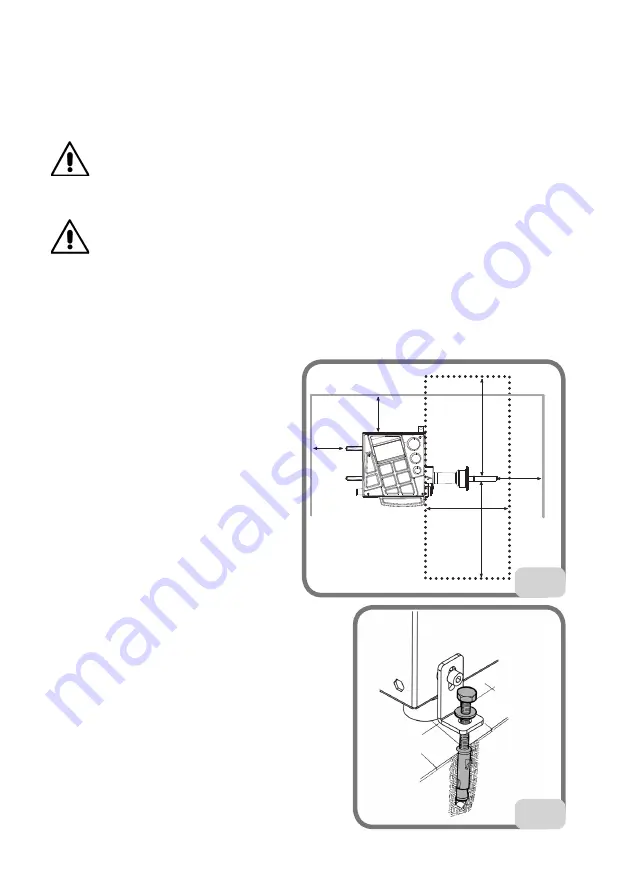

Fixing the machine to the ground (Fig. 5)

The machine is to be fixed to the ground if:

- It does not have the accessory triangular

foot.

- If it does have the accessory triangular

foot but is going to be used with wheels

heavier than 50Kg. In such a case the

triangular foot will have to be removed

in order to fix the front bracket.

- Undo the three M8x60 hex head screws

fastening the machine to the pallet.

- Remove the plastic washers between

the casing and the three L brackets:

these brackets will be used to fasten the

machine to the floor.

- Refit the brackets on the machine in the

original positions, without tightening the screws.

- Position the machine on the ground in the selected

position and make sure that the surrounding

spaces correspond to the minimum values indi-

cated in Fig. 4.

- Trace the position for drilling on the floor.

- Drill in the traced position and then take the

included Fischer M8 and insert them into the

holes that were made.

- Secure the machine to the floor by fastening the

L brackets to the Fischer anchor bolts using the

relative screws and washers (fig.5).

- Tighten the three fastener screws to the casing.

1000

1000

600

600

3000

3000

4

5