B 215 / B 225 Evo

Operator’s manual

85

UK

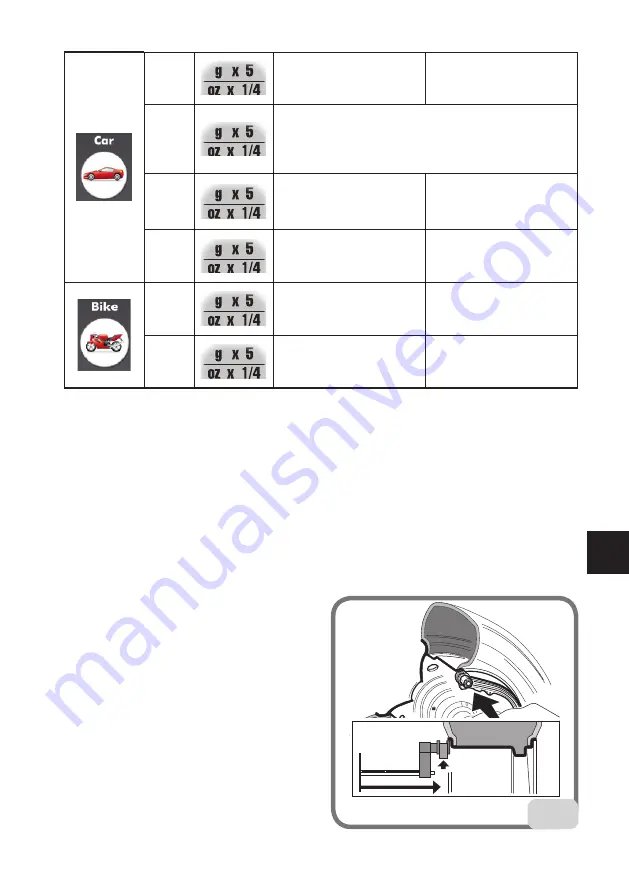

ALU 5

adhesive weight to

apply manually at the

12* o'clock position.

clip weight to apply

manually at the 12 o'clock

position

STA

clip or adhesive weight to apply manually at the

12 o'clock position either on the outer or inner side or

at the centre of the rim well clip weight to be applied

manually at the 12 o'clock position

ALU 1

Adhesive weight to

apply manually at the

12* o'clock position

Adhesive weight to

apply manually at the

12* o'clock position

ALU 2

clip weight to apply

manually at the 12 o'clock

position

Adhesive weight to

apply manually at the

12* o'clock position.

dyn

BIKE

clip weight to apply

manually at the 12 o'clock

position

clip weight to apply

manually at the 12 o'clock

position

ALU

BIKE

adhesive weight to

apply manually at the

12* o'clock position.

adhesive weight to

apply manually at the

12* o'clock position.

*The machine allows the operator to change the application position of the adhesive

weight from o'clock to 12 o'clock using the CLIP weight holder or 6 o'clock using the LASER

line la based on his requirements.

To change the application position for the adhesive weights, follow the instructions in the

set up menu "Adhesive weight application position ”.

3. ENTERING WHEEL DIMENSIONS (ALU1P

AND ALU2P PROGRAMMES EXCLUDED)

Wheel data entry for wheel bal-

ancers without outer mechani-

cal sensor

The machine allows for the diameter and

distance values to be entered automati-

cally; the width value can be entered using

the keypad.

- Bring the automatic measuring arm into

contact with the inner side of the rim (fig.11).

Take great care to position the arm correctly

so as to ensure accurate data reading.

While moving the automatic arm, the distance

measured by the arm is shown on the display:

11