Solve image-quality problems

Image defect examples

These examples identify the most common print-quality problems.

Table 2-34

Image defect examples

Problem

Image example

Solution

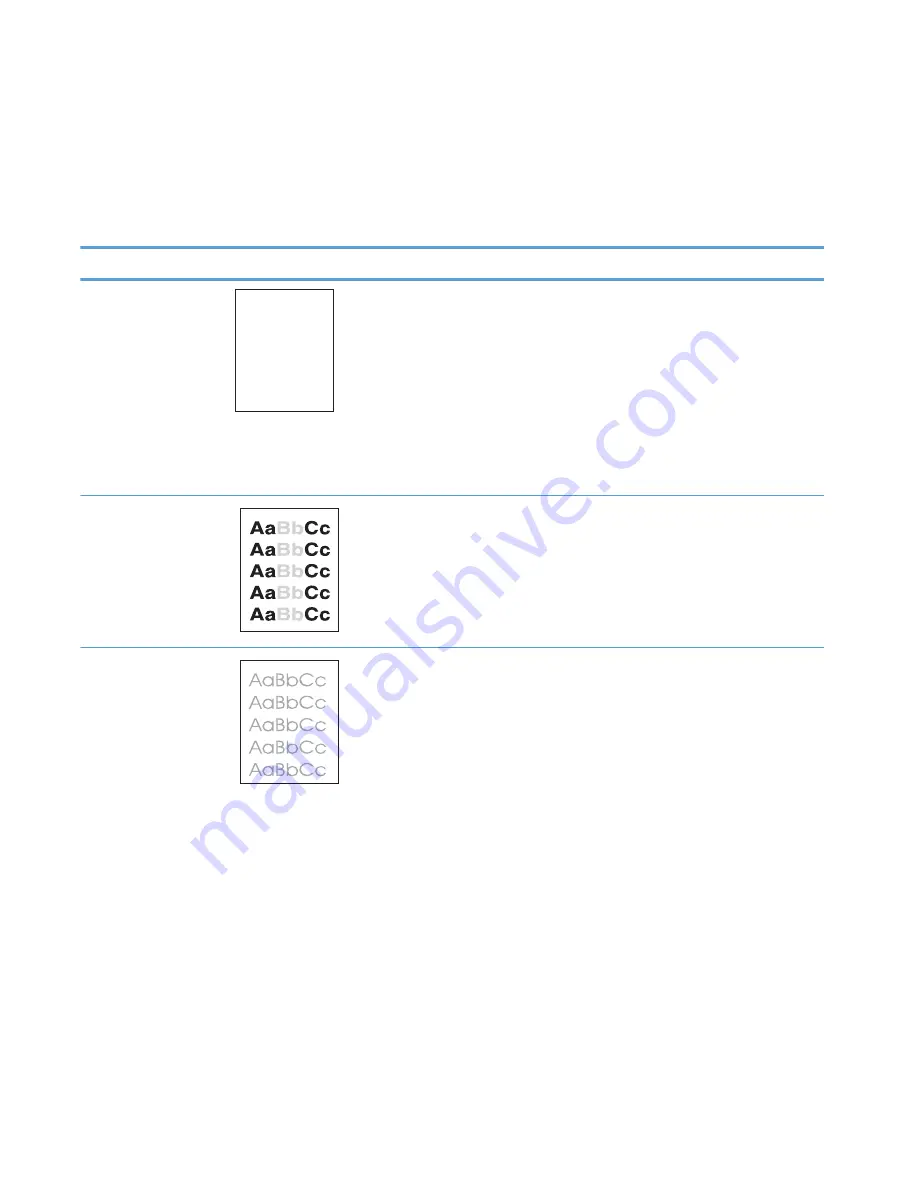

Blank page

1.

The laser/scanner shutter on the toner cartridge might be damaged. Replace

the toner cartridge.

2.

The laser/scanner shutter on the laser/scanner might be damaged. Replace

the laser/scanner.

3.

The laser/scanner might be damaged. Replace the laser/scanner.

4.

Poor developing bias with the cartridge contacts. Clean the contact on the

toner cartridge.

5.

The high-voltage power supply might be damaged. Replace the high-voltage

power supply.

Light print (partial page)

1.

Make sure that the toner cartridge is fully installed.

2.

The toner cartridge might be almost empty. Check the supplies status, and

replace the toner cartridge if necessary.

3.

The paper might not meet HP specifications (for example, the paper is too

moist or too rough).

Light print (entire page)

1.

Make sure that the toner cartridge is fully installed.

2.

Make sure that the

Economode

setting is turned off at the control panel and in

the print driver. For more information, see the product user guide.

3.

Open the

Administration

menu at the product control panel. Open the

General Settings

menu, and then open the

Print Quality

menu. Increase the

Toner density

setting.

4.

Try using a different type of paper.

5.

The toner cartridge might be reaching its estimated end of life. Check the

supplies status, and replace the toner cartridge if necessary. Try the following:

432

Chapter 2 Solve problems

ENWW

Summary of Contents for LASERJET ENTERPRISE MFP M725dn

Page 1: ...LASERJET ENTERPRISE MFP M725 Troubleshooting Manual M725z M725dn M725f M725z ...

Page 2: ......

Page 3: ...HP LaserJet Enterprise MFP M725 Troubleshooting Manual ...

Page 6: ...iv Conventions used in this guide ENWW ...

Page 32: ...xxx ENWW ...

Page 142: ...110 Chapter 1 Theory of operation ENWW ...

Page 457: ...4 Close the fuser jam access cover 5 Close the fuser door ENWW Clear jams 425 ...

Page 475: ...1 Lift the document feeder latch 2 Open the document feeder cover ENWW Clean the product 443 ...

Page 516: ...484 Appendix A Service and support ENWW ...

Page 545: ......

Page 546: ... 2013 Hewlett Packard Development Company L P www hp com CF066 91023 CF066 91023 CF066 91023 ...