BA_PH_245-20_EN_15-22.docx

53

16.9

Tenoning and Slotting Device Type 1376

The tenoning and slotting device 1376 is used for tenoning and slotting on the tilting spindle moulder. It is usually

already factory-fitted to the table top of the machine. The integrated mitre fence can be swivelled by 60° to both

sides and enables angular cuts from 30° to 150°. The smooth-running, ball-bearing sliding carriage has a sliding

length of 710 mm (sliding panel length = 295 mm, slide panel width = 255 mm).

Increased risk of accidents due to the high weight of the device! Lifting and placing

should be done by two persons or with a suitable hoist (e.g. indoor crane)!

•

Danger of crushing hands and fingers between the device and the machine table!

•

Wear protective gloves when lifting or placing the device.

•

Acute risk of injury to the feet if the device falls down!

•

Wear safety shoes with steel toecaps.

Note for possible retrofitting:

If the device is retrofitted later, it must be mechanically adapted to the machine

table on site. For this purpose, the table top must be provided with corresponding threaded holes. For procedure

and drilling sketch refer to section

16.9.1

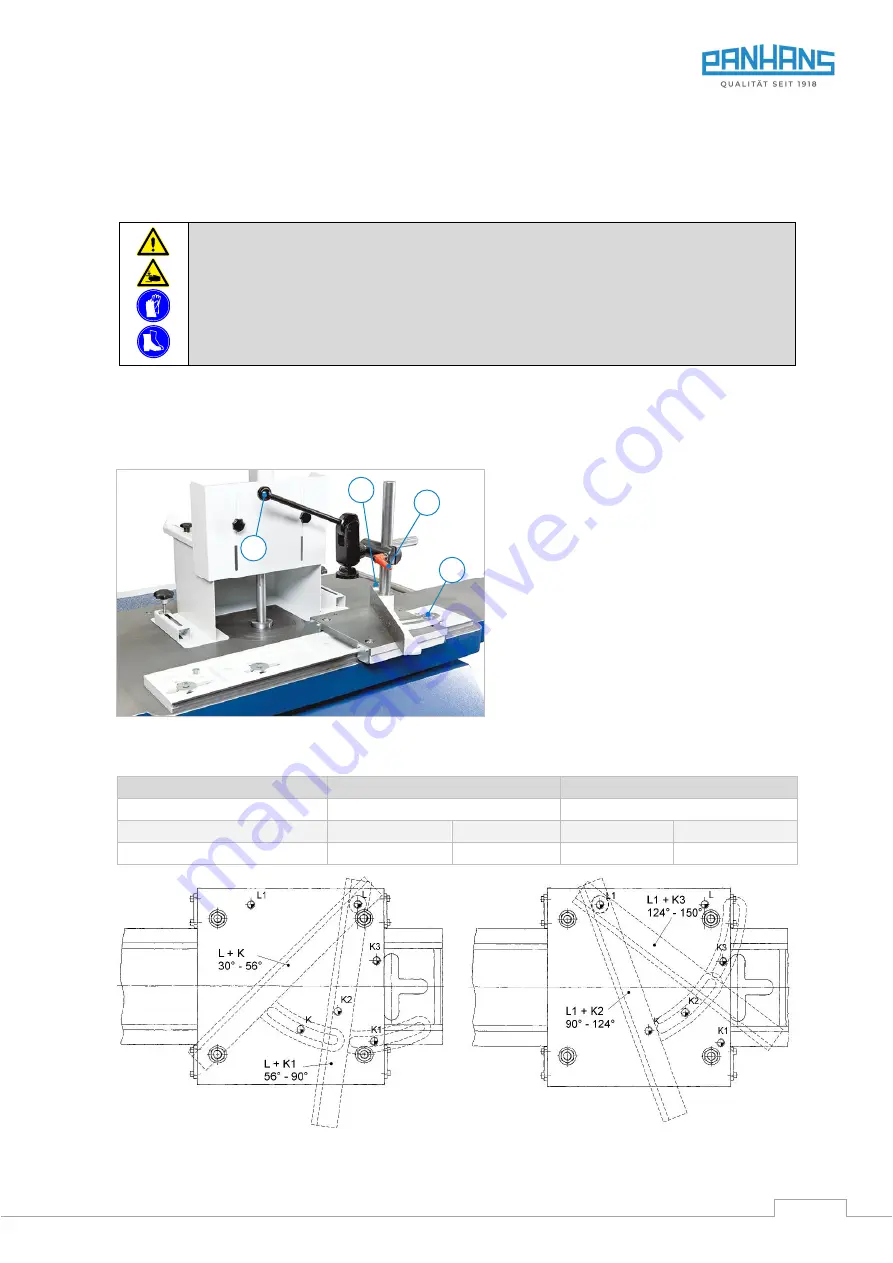

Operation

Figure 51: Tenoning guard 1376

Workpieces to be machined can quickly and se-

curely be fixed on the slide with the eccentric

clamp (

E

). The position of the eccentric clamp

can be adjusted to the respective workpiece. To

adjust, loosen the clamping levers (

H

).

The bearing screw (

L

) and the clamping screw

(

K

) are used to adjust angles. Depending on the

desired angle range, these can be shifted ac-

cordingly to the table in section

Maintenance see section

Article number see section

16.9.2

Table for Angular Cuts

Demanded cutting angle

30°

…

90°

90°

…

150°

Bearing point

L

L1

Clamping point

K

K1

K2

K3

Cutting angle range

30°... 56°

56°... 90°

90°... 124°

124°... 150°

Figure 52: Angle ranges (position of the screws)

H

E

K

L