Remove the screws that hold the servo horns

in place and adjust the horns so that they are

perpendicular to the servo. This will be their

neutral position. It is a good idea to use single

arm servo horns rather than the round horns

most servos come with. The sketch shows how

to cut a horn for use here. Reinstall the screws

that hold the horns in place.

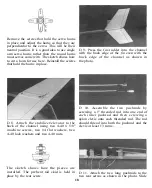

D 9. Press the fin/rudder into the channel

with the back edge of the fin even with the

back edge of the channel as shown in

the photo.

D 8. Attach the stabilizer/elevator to the

back of the channel using two 4-40 x 5/8"

machine screws, two #4 flat washers, two

4-40 lock washers and two 4-40 nuts.

D 10. Assemble the two pushrods by

screwing a 1" threaded rod into one end of

each inner pushrod and then screwing a

nylon clevis onto each threaded rod. The rod

should thread into both the pushrod and the

clevis at least 13 turns.

The sketch shows how the pieces are

installed. The prebent tail skid is held in

place by the rear screw.

D 11. Attach the two long pushrods to the

two rear servos as shown in the photo. Slide

18