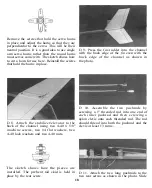

D 10. Insert the hinges into the slots and

trial fit the ailerons in place on the wing. Do

not glue the hinges until after you have

covered the wing. Sand the outboard edge of

the sub trailing edges and the ailerons to

match the foam wing tips.

JOIN THE WING PANELS

D 1. Use a sanding block with some fine grit

sandpaper (240 - 320 grit) to remove the little

nubs and any mold lines left on the wing

from the molding process.

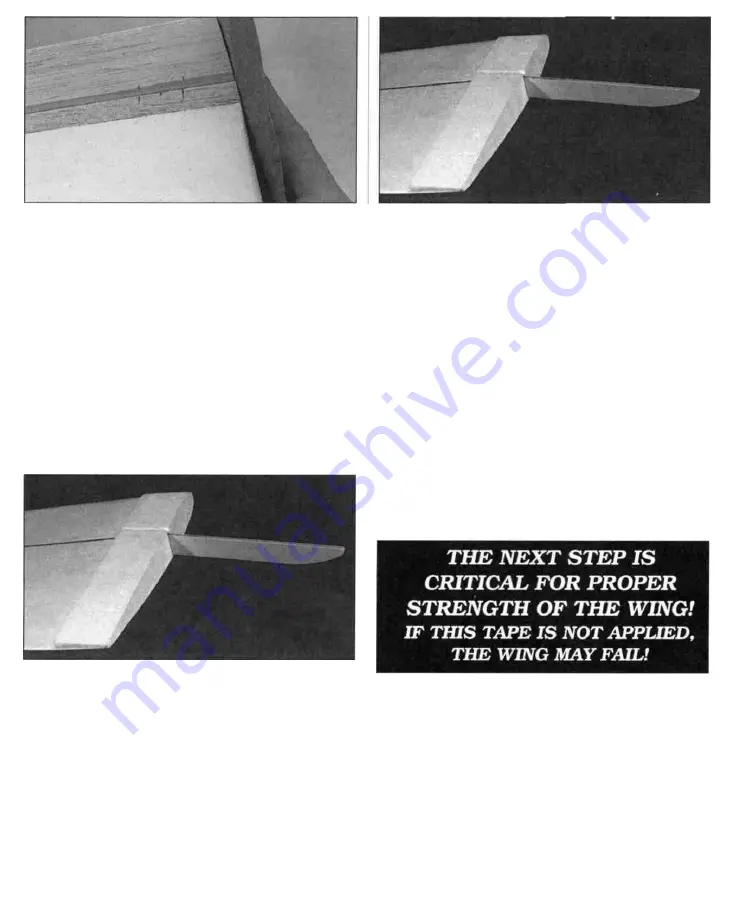

D 2. Test fit the 1/8" plywood dihedral joiner

in the slots in the wing to make sure it fits

nicely. Mix up about 1/2 oz. of epoxy and

spread it throughout the slot in one wing

panel. With the wing panel upside down,

insert the joiner in place and squeeze out all

the excess epoxy so that the joiner is flush

with the bottom of the wing (which is facing

up). Try to use enough epoxy so that the slot

is completely full and level with the surface of

the wing.

D 3. Lay some wax paper down on the work

surface and mix up one ounce of epoxy.

Spread the epoxy throughout the slot and on

the root (middle end) of the other wing panel.

Slide the two wing panels together and line

them up as close as possible. Use several

T-pins and masking tape to help hold them in

alignment. Flip the wing assembly over so that

the bottom of the wings are facing up and

make sure that the joiner is seated properly in

the slot. Wipe off any excess epoxy before it

starts to cure. It is important that the wings

are joined with both panels being accurately

aligned with each other.

D 4. Allow the epoxy from the last step to

fully cure.

Note: The tape used in this step is 3/4" wide

nylon filament reinforcing tape. This is

self-adhesive tape with nylon filaments

running the length of the tape. It is also

referred to as "nylon filament strapping tape,"

or "nylon reinforced packaging tape." You can

obtain it at any store that sells stationery and

packaging materials or at most hardware

stores. Be sure to use 3/4" wide tape.

Narrower tape will not provide the wing with

12