wing if necessary to make the protector lie

flat against the wing. When satisfied with

the fit, remove the servo. Use coarse

sandpaper to roughen the bottom of the wing

protector so the glue will hold better. Use

epoxy to glue the protector in place.

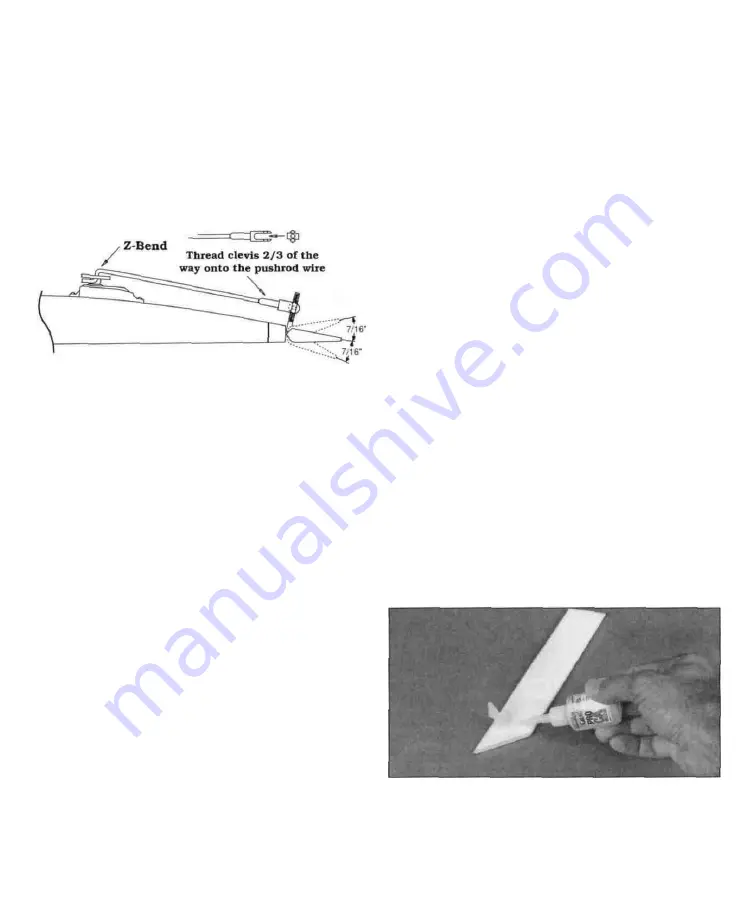

D 5. Trial fit the ailerons for this step. Mount

the aileron servo with the screws provided in

the radio system and assemble the pushrods

as shown in the sketch above. Attach the

pushrods to the torque rods by screwing the

Aileron Clevis Connector onto the threaded

portion of the torque rod. Use a pair of needle

nose pliers to make the Z-bends and attach

them to the servo horn. Turn on your radio.

plug in your aileron servo and adjust the

centering of the servo horn u n t i l it is

centered and the right aileron moves up

when you move the transmitter stick to the

right. Adjust the nylon clevis until each

aileron is in a neutral position when the

transmitter sticks and trims are centered.

Also adjust the position of the nylon clevis

connector on the torque rod to achieve 7/16"

of up and down movement.

COVERING

D 1. The tail surfaces (fin, rudder, stabilizer

and elevator) should be covered with one of

the iron-on coverings to help protect them

from becoming fuel soaked and ruined. If you

are also going to cover the wing, which will

help it look nicer longer (and add a

small amount of strength), you can save a

little money by buying only one roll of low

temperature covering (EconoKote, Black

Baron Film, etc.) and using it for both the

wing and the tail surfaces. Otherwise you can

use any type of covering for the tail surfaces,

but remember to use a low heat covering for

the wing. A few stripes or your AMA number

can really add to the looks of your STURDY

BIRDY II.

D 2. Follow the instructions that come with

the covering and cover the tail surfaces at

this time. It is a good idea to cover the bottom

surfaces first to get familiar with the covering

since these surfaces will normally not be

seen. When covering the wing, cover right

over the tape and plastic wing protector. Try

to use as little heat as possible.

ATTACHING THE CONTROL HORNS

D 1. Position the nylon control horn on the

left side of the rudder about 1" up from the

bottom with the four holes lined up with the

leading edge. Use a drop of Thin CA to tack

glue the horn in place.

14