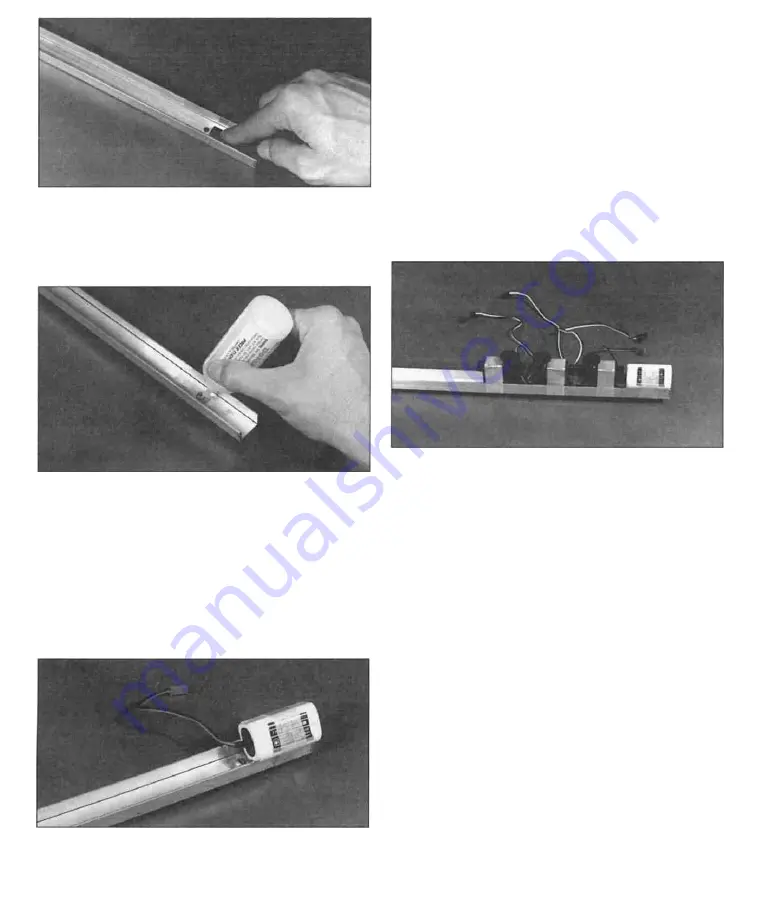

end of the channel. Square battery packs fit

nicely but most flat packs will also fit. Just

tape them flat onto the channel. The battery

should protrude approximately 1/8" past the

end of the channel to keep the fuel tank from

rubbing against the end of the channel.

D 4. Use a small piece of coarse sandpaper

to scuff up the inner floor of the aluminum

channel in the area around the front 11/64"

bolt hole.

D 5. Insert one of the 8-32 x 1/2" machine

screws into the hole so that it sticks out the

bottom of the channel and glue it in place

with plenty of thick C A or epoxy. This screw

w i l l be covered by the b a t t e r y pack,

prohibiting a screwdriver from being used to

keep it from turning. Glue it securely, but be

careful not to get any glue on the threads.

D 6. Use some nylon reinforced strapping tape

to securely hold the battery pack on the front

D 7. The servos are "press fit" into the

aluminum channel and then held in place with

nylon strapping tape. Standard size servos

should fit very nicely and smaller servos can be

held in place by using a piece of wood to fill the

space between the servo sides and the channel.

Large servos will not work in the STURDY

BIRDY II. The servos should be placed as far

forward in the channel as possible and right

next to each other, but do not overlap the servo

mounting lugs. The front two servos should be

mounted with their servo output shafts

towards the back of the plane and the back

servo should have its output shaft towards the

front of the plane. The servo wires should be

routed out to the side of the servo without

going under any servos. Wrap two layers of

nylon strapping tape all the way around each

servo and the aluminum channel to hold it in

place. Hook up the entire radio system and

turn it on (see the instructions included with

your radio). Adjust the transmitter trims so

they are in the middle of their slots.

17