pin through the center of each hinge, before

installing. This pin will keep the hinge

centered while installing the control surface.

Note: When hinging the ailerons, which use

torque rods, use a toothpick to force epoxy

down the hole drilled for the torque rod. In

the case of the rudder, be sure not to let glue

get into the bearing tube.

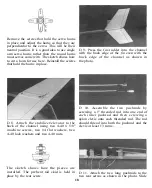

D 6. Trial fit the fin and rudder together using

the hinges to check for proper alignment.

Do Not glue the hinges in place yet! Sand the

rudder and/or fin so they match each other at

the top.

above. Use a razor saw to cut the excess off at

the leading and trailing edges.

D 9. Check the fit of the fin assembly into

the aluminum channel. It will most likely be

a little loose and we want a nice, tight fit. Add

a strip of the 1/64" plywood doubler to ONE

side of the fin. Glue it to the balsa doubler.

Check the fit again and if it is still a little

loose, add a plywood doubler to the other

side. If necessary, you can sand the plywood

slightly to help the assembly fit. Also, you

can have the covering material continue

down over the doublers if you need the

additional thickness.

D 7. Remove the hinges from the

rudder and bevel the leading edge

with your sanding block as shown in

the sketch. This is to allow the

EDGE VIEW

rudder to swing either direction once

the hinges are glued in place.

D 8. Add the 1/4" x 1/2" balsa doubler to

each side of the fin as shown in the photo

D 10. Position the fin assembly in the channel

with the trailing edge of the fin even with the

end of the channel. Press it in place. Mark the

location of the stabilizer bolt holes on the

bottom of the fin and then remove the fin from

the channel.

7