www.hi-velocity.com

© 1995-2020 Energy Saving Products Ltd.

© 1995-2020 Energy Saving Products Ltd.

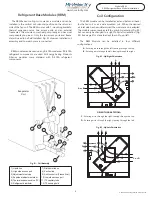

The Return Air is to be sized on a 0.15 static pressure (37 pa) as

compared to 0.10 static pressure (25 pa) for conventional forced

air systems. The maximum length for an individual return air duct

is fifty feet (15.24m).

Duct Sizing

Please note: It is VERY important NOT

to undersize the return air, as this will

create noise, increase motor power

consumption, reduce airflow and increase

the possibility of condensate carry-over.

Table 03 has recommended return air sizes for round and

rectangular ducts. A variance of

+20%

is allowable for sizing

return ducts that connect to the RBM or Hi-Velocity Systems unit.

Where allowed by local codes, a single return air grill may be

used. Note: Return air grill must have equal minimum of free air

area to return air.

Table 03 – Return Air Duct Sizes

Unit

Rigid Ø

Flex Ø

Min Sq.

Inches

(Sq. cm)

50/51/52

12”

(305mm)

14”

(356mm)

120

(774cm)

70/71

12”

(305mm)

14”

(356mm)

120

(774cm)

100/101

14”

(356mm)

16”

(406mm)

168

(1084cm)

Remember: When using flexible duct for return air, use

one duct size larger due to the higher friction loss.

Important: When connecting a round

Return Air to the RBM coil, a round to

rectangular transition is required.

Specifications

RBM-50

RBM-70

RBM-100

Matching Fan Coil

HE-Z/HE-B/HE-50/51

HV-50/51/52

CU-51

LV-50

HE-Z/HE-B/HE/HV-70/71

LV-70

HE-Z/HE-P/HE-B/HE/HV-100/101

Part Number

41090300050

41090300070

41090300100

Tons

(1)

1.5 - 2.0

(5.3 - 7.0 kW)

2.5 - 3.0

(8.8 - 10.6 kW)

3.5 - 5.0

(12.3 - 17.6 kW)

Refrigerant Type

R-410A

R-410A

R-410A

TX Cooling MBH

(2)

18-24

(5.3-7.0 kW)

30-36

(8.8-10.6 kW)

42-60

(12.3-17.6 kW)

Latent Cooling MBH

6.8-8.9

(2.0-2.6 kW)

11.7-13.7

(3.4-4.0 kW)

16.0-22.2

(4.7-6.5 kW)

Fin Material

Aluminum

Aluminum

Aluminum

Tubing Material

Copper

Copper

Copper

Type of Fins

.006 Al

(0.1524mm)

.006 Al

(0.1524mm)

.006 Al

(0.1524mm)

Connection

Sizes

Liquid Line (Lq)

3/8

”

(9.5mm)

3/8

”

(9.5mm)

3/8

”

(9.5mm)

Suction Line (S)

7/8

”

(22.3mm)

7/8

”

(22.3mm)

7/8

”

(22.3mm)

Drain Connection

3/4

”

M CPVC

(19mm)

3/4

”

M CPVC

(19mm)

3/4

”

M CPVC

(19mm)

TXV with Built in Check Valve & Bypass

Pre-Installed

Pre-Installed

Pre-Installed

Access Ports

Yes

Yes

Yes

Freeze Stat

Yes

Yes

Yes

Shipping Weight

35 lbs

(15.9 kg)

45 lbs

(20.4 kg)

55 lbs

(24.9 kg)

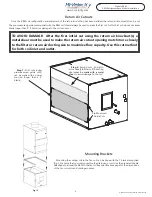

Module Size (L x W x H)

14

1

⁄2

”

x 18

1

⁄4

”

x 18

1

⁄4

”

(368mm x 464mm x 464mm)

19

1

⁄2

”

x 18

1

⁄4

”

x 18

1

⁄4

”

(495mm x 464mm x 464mm)

25

1

⁄2

”

x 18

1

⁄4

”

x 18

1

⁄4

”

(648mm x 464mm x 464mm)

-9-

-9-

Important: When using flexible duct for

return air, use one duct size larger due to

the higher friction loss.

Module RBM

RBM Refrigerant Base Module Installation

(2) Smaller condensers may be matched to the fan coil when needed (match TXV to condenser size)

(1) Minimum of

Minimum of

four HE outlets

four HE outlets

per ton of cooling needed. (2” Duct = Minimum

per ton of cooling needed. (2” Duct = Minimum

eight outlets

eight outlets

per ton)

per ton)

MBH - Thousand British Thermal Units per Hour

TX - Thermal Expansion

TXV - Thermal Expansion Valve

Summary of Contents for RBM-100

Page 2: ......