www.hi-velocity.com

© 1995-2020 Energy Saving Products Ltd.

© 1995-2020 Energy Saving Products Ltd.

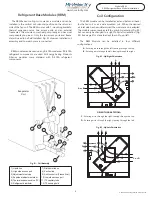

Thermal Expansion Valve & Sensing Bulb

The Thermal Expansion (TX) Valve comes pre-installed inside

the RBM Module. It is acccessible through the easy to remove

front door or access hatch. The access hatch is used to access

the TXV and the adjustment stem after the line sets are brazed

on, and can be adjusted while the system is running. The TXV’s

sensing bulb is pre-installed on a clean, horizontal section of the

suction line. It will be mounted on the top half of the pipe in

the 2 o’clock or 10 o’clock position. (Fig. 13) When brazing near

components always use a wet rag or heat dissipating paste to

avoid damage or overheating any compontents. Failure to do

so may void warranty.

Fig. 13 - TX Sensing Bulb

Access Ports

When refrigerant lines are connected to the RBM coil, high

and low side access ports must be connected as well. (Fig. 01 -

reference 2 & 10) With the use of a tee and reducer this process

is simplified. The access ports are required for system startup and

for future trouble shooting or service. When reading refrigerant

pressures/temperatures, always read them at the evaporator

access ports.

External Equalizer Line

The external equalizer line comes pre-installed off of the

TX Valve’s body and runs to the suction line. It is required to

compensate for refrigerant pressure drop through the coil.

Freeze Stat

The RBM Series cooling module comes with an

anti-freeze control. This freeze control serves the

purpose of preventing severe icing of the coil in the

event of an undercharge or low load on the coil.

During start-up, it is acceptable to jumper across the Freeze-

Stat. This will prevent the freeze-stat from shutting the system

off while charging a new system that may be low on refrigerant.

Once charged and running, this jumper must be removed and the

Freeze-Stat connected to the FZ and FZ terminals on the Printed

Circuit Board. Should wiring needs arise in which the outdoor unit

is controlled through another means of wiring, the Freeze-Stat

should be connected in series on the input side of the control

wiring.

Refrigerant Bypass

All RBM coils come with a pre-installed check valve ready TX

valve, used for AC only or heat pump condensing units. Third

party TX valves may require a bypass check valve.

Fig. 14- Bypass check valve

-6-

-6-

Freeze-Stat

Sensing

Bulb

10 o’clock

2 o’clock

12 o’clock

END

VIEW

Sensing

Bulb

Sensing

Bulb

Freeze-Stat

Important: Anti-freeze control must be

used at all times. Failure to do so may

void warranty.

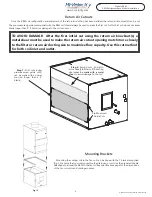

Stand/Riser

Capped

Cleanout

P-Trap

Secondary

Drain

Primary

Drain

Fig. 15 - Example of Recommended Condensate Piping

Drain Connections, P - Trap &

Secondary Drain Pan

The primary condensate drain

must have a minimum 3”

P-Trap installed

(Fig. 15). The drain line must run at a slope of

¼” per foot in the direction of the drain. RBM modules come

with a ¾” male CPVC primary and secondary outlet. It is good

practice to install a clean out right above the P-Trap. Using a

“tee fitting” and cap in the P-Trap’s construction can be used as

the clean out and as a way to prime the P-Trap if it ever dries out.

A wet P-Trap is important. A dry P-Trap can be detrimental to

proper drainage. If code requires a secondary drain line, run the

secondary line using the same method as primary. Otherwise,

capping off the secondary drain line is acceptable.

Do not run the

secondary drain line to the secondary drain pan or use it as a vent

to atmosphere!

An equipment stand/riser or rubber equipment

mat may be necessary to elevate the module off of the ground to

allow for a P-Trap.

Any installation that has the potential of property damage

due to condensate must have a secondary drain pan installed. If

the unit is installed in a high heat and/or high humidity location,

extra insulation around the unit casing may be required. This will

prevent excessive condensate from forming on the outer surface

of the casing.

Important: Piping the condensate lines on a return side cooling

coil can be dramatically different, be sure to read info below.

Module RBM

RBM Refrigerant Base Module Installation

Summary of Contents for RBM-100

Page 2: ......