www.hi-velocity.com

© 1995-2020 Energy Saving Products Ltd.

© 1995-2020 Energy Saving Products Ltd.

Heat Pumps

Traditionally, SDHV systems have been charged to special

guidelines when used in conjunction with heat pumps. This

charging procedure involved charging the units to normal

cooling capacities and reviewing the operation in heating mode.

If head pressures were found to be impinging on the high head

pressure limits, a small amount of refrigerant was removed to

prevent the unit from shutting down. The cause of high head

pressures in heating mode is due to the disparity in sizes of the

indoor and outdoor coils, along with the lower airflow rates of

SDHV systems.

The RBM coil can operate at a level that is different from

most other conventional system coils. Typically, superheat levels

are slightly lower at 6-10°F (1 - 3°C) of superheat. Adjustment

of the valve also differs somewhat. Rather than having a large

effect on the range of superheat, adjustment of the valve has

a larger effect on the system pressures; superheat maintaining

a fairly constant point. Opening the valve will increase suction

pressures and decrease liquid pressures, while closing the valve

will decrease suction pressures and raise liquid pressures.

Bi-Flow Receiver

The Bi-Flow Receiver is designed

for use with heat pump systems,

up to 5 tons, and with any typical

refrigerants. The receiver provides

a location for the storage of excess

refrigerant during the heating cycle,

minimizing head pressures. During

cooling mode, the receiver is empty,

allowing the full refrigerant charge to

be utilized for cooling.

The receiver is a horizontal tank with a pair of dip tubes

extending to the bottom of the tank. These two tubes allow for

liquid refrigerant to be drawn from the tank regardless of the

direction of flow. For this reason, the receiver must be mounted

so that the inlet/outlets of the tank come out of the top of the

unit. Mounting brackets are located at the base of the unit for

secure mounting. The receiver is to be located on the liquid line

of the system, anywhere between the indoor and outdoor coils.

As the unit is of a bi-flow design, it does not matter which end

faces towards the indoor coil.

The inlet/outlet ports are constructed of steel and require

the use of a 35-45% Silver Solder and Flux for brazing. The use

of standard copper to copper solders may result in difficulty

brazing and the potential for a failure at the weld. Ensure

that the tank is protected from overheating while brazing and

that any remaining flux is cleaned from the unit. If installing

outdoors, ensure that the receiver is insulated and protected

from the elements.

With the introduction of newer, larger heat pumps, this issue

is more likely to be experienced. While some heat pump units

may still be charged in the traditional method, the amount of

refrigerant that is required to be removed for heating mode may

leave the system drastically undercharged for cooling mode. For

this reason it is highly recommended that a Bi-Flow Receiver be

used with heat pump applications.

Charging (Continued)

Typical Operating Ranges

Saturated Suction Temperature

34 - 40°F (1 - 4°C)

Suction Line Temperature

38 - 44°F (3 - 7°C)

Superheat

6 - 10°F (1 - 3°C)

Suction Line Pressure (R-410A)

110-124 psig (7.5-8.5 bar)

Liquid Line Pressure (R-410A)

250-300 psig (17-20.5 bar)

Return Air

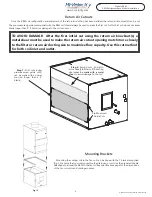

When designing the return air for a Hi-Velocity System, there

are a few things to consider. It is common to use centralized

return air with systems that have rooms that are within a

common area. Separate floors or rooms that have high loads

and require a large amount of supply air flow should have their

own return air, or be tied into the centralized return air to allow

the air to return back to the fan coil. Rooms or areas that cannot

be tied into the return air should have an air transfer grill to

allow the air to escape the room and flow back to a centralized

return air.

-8-

-8-

Important: Return Air must be filtered

before entering the cooling module.

Module RBM

RBM Refrigerant Base Module Installation

Summary of Contents for RBM-100

Page 2: ......