www.hi-velocity.com

© 1995-2020 Energy Saving Products Ltd.

© 1995-2020 Energy Saving Products Ltd.

Refrigerant Base Modules (RBM)

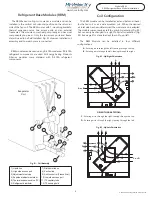

The RBM Series cooling coil comes as a module and can be

installed in the vertical or horizontal position on the return air

side of the fan coil. The RBM comes with T-mounting brackets,

thermal expansion valve, two access ports, and an external

freeze stat. This module comes heat pump ready and has most

components pre-piped. Only the two access ports and freeze

stat will need to be field installed. Fig. 01 shows an installed coil

assembly and how each piece is connected.

1) Liquid line

2) High side access port

3) Adjustment stem cap

4) Superheat adjustment stem

5) Thermal expansion valve (TX)

6) Refrigerant distributor

7) Distributor tubes

8) Suction line

9) Anti-ice control (Freeze Stat)

10) Low side access port

11) TX capillary tube

12) TX sensing bulb

RBM modules can be used on any R-410A condenser if R-410A

refrigerant components are used. All Energy Saving Products

R-Series modules come standard with R-410A refrigerant

components.

-3-

-3-

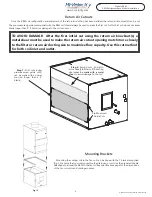

The RBM module can be installed as a stand (return air base)

for the fan coil or as a side mounted coil. When the desired

air inlet side has been determined, the module can be adapted.

The module comes ready as left to up/right orientation (Fig. 02)

but can easily be changed to a right to up/left orientation. (Fig.

03) See page 3 for steps to adapt the coil to up/left.

The RBM Module can be installed in four different

configurations:

A

- Entering air in through the left, leaving through the top.

B

- Entering air in through the left, leaving through the right.

C

- Entering air in through the right, leaving through the top.

D

- Entering air in through the right, leaving through the left.

A

A or B

B

Fig. 02 - Up/Right Orientation

OR (WITH ADAPTATION)

C

C or D

D

Fig. 03 - Up/Left Orientation

1

9

8

7

6

5

4

3

2

10

11

12

Evaporator

Coil

Fig. 01 - Coil Assembly

Coil Configuration

Module RBM

RBM Refrigerant Base Module Installation

Summary of Contents for RBM-100

Page 2: ......