www.hi-velocity.com

© 1995-2020 Energy Saving Products Ltd.

© 1995-2020 Energy Saving Products Ltd.

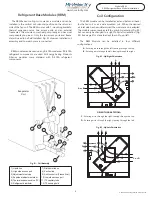

Piping the RBM

Only refrigerant grade pipe and fittings are to be used with

the RBM Module. Plumbing fittings may contain wax or other

contaminants which are detrimental to the proper operation of

the system. Insulate the suction line with a minumum of 3/8”

insulation. In high heat areas, a minimum of 1/2” insulation may

be needed. If the lines are run in an area where temperatures

could exceed 120°F or runs longer than 50’, then the liquid line

may need to be insulated as well. Support the pipe every 5 feet,

or whatever local code states.

Run the pipes in the most direct route possible, taking into

account structural integrity, building details and local building

codes. If the evaporator is located above the condenser, slope

any horizontal runs toward the condenser. If the condenser is

located above the evaporator, a P-trap must be installed at the

bottom of the vertical riser. For long vertical risers, additional

P-traps must be installed for every twenty feet. For lines running

over 50’, a suction line accumulator must be installed. Lines

running over 100’ are not recommended.

Pipe Sizing

Tables 01 and 02 contain line sizing information for the liquid

and suction lines.

The sizes given in the above tables are only for general reference, if the

condenser manufacture requires a different size than specified in

Table 01

and

Table 02

, their sizing shall be used whenever a discrepancy occurs.

Table 01 – Liquid Line sizes

Tons

Distance

1

1

1

⁄

2

2

2

1

⁄

2

3

3

1

⁄

2

4

5

1’–25’

1

⁄

4

1

⁄

4

5

⁄

16

3

⁄

8

3

⁄

8

3

⁄

8

3

⁄

8

1

⁄

2

26’–50’

5

⁄

16

5

⁄

16

3

⁄

8

3

⁄

8

1

⁄

2

1

⁄

2

1

⁄

2

1

⁄

2

51’–75’

3

⁄

8

3

⁄

8

3

⁄

8

1

⁄

2

1

⁄

2

1

⁄

2

1

⁄

2

1

⁄

2

76’–100’

3

⁄

8

3

⁄

8

1

⁄

2

1

⁄

2

1

⁄

2

1

⁄

2

1

⁄

2

1

⁄

2

Table 02 – Suction Line sizes

Tons

Distance

1

1

1

⁄

2

2

2

1

⁄

2

3

3

1

⁄

2

4

5

1’–25’

5

⁄

8

5

⁄

8

3

⁄

4

3

⁄

4

3

⁄

4

7

⁄

8

7

⁄

8

1

26’–50’

5

⁄

8

3

⁄

4

3

⁄

4

3

⁄

4

7

⁄

8

7

⁄

8

1

1

⁄

8

1

1

⁄

8

51’–75’

3

⁄

4

3

⁄

4

7

⁄

8

7

⁄

8

1

1

⁄

8

1

1

⁄

8

1

1

⁄

8

1

1

⁄

8

76’–100’

3

⁄

4

7

⁄

8

7

⁄

8

1

1

⁄

8

1

1

⁄

8

1

1

⁄

8

1

1

⁄

8

1

1

⁄

8

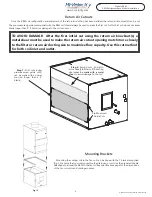

Outdoor Unit Installation

Locate the outdoor unit in a suitable location, as close as

possible to the fan coil. Maintain the clearances recommended

by the manufacturers of the outdoor unit, to ensure proper

airflow. The outdoor unit must be installed level, in a properly

supported location. A liquid line filter/drier is recommended to

be installed.

Wiring – Outdoor Unit

Make all connections to the outdoor unit with rain tight

conduit and fittings. Most building codes require a rain tight

disconnect switch at the outdoor unit as well (always check

local codes). Run the proper size copper wires to the unit, and

connect as per the manufacturer’s recommendations.

Ensure that the unit is setup for a TX system. If not, a hard

start kit may be required.

Evacuating

The system must be brazed under a nitrogen purge to

prevent oxidation of the pipe during the brazing process. After

the piping is installed and all components have been brazed

together, a vacuum pump must be used to properly evacuate

the system from both of the access ports to 1500 microns, to

ensure system is free of contaminants. Add refrigerant to the

system to bring the pressure above zero psig. After allowing

the refrigerant to absorb moisture, repeat the above procedure.

Evacuate the system to 500 microns on the second evacuation,

and ensure that the system holds at the vacuum pressure. If not,

check for leaks and evacuate again. If the vacuum holds, add

refrigerant to raise the pressure to 2 psig. At this point open

service valves on pre-charged condensing units.

The use of an electronic leak detector is recommended, as it is

more sensitive to small leaks under the low pressures.

Once the system has been determined clean and ready for

charging, refrigerant can be added. The service valves on the

condenser must be open at this point. Never leave the system

unattended when charging. With the system running, slowly

add refrigerant. The typical operating point of an RBM coil is

that of a saturated suction temperature of 34-40°F at 100-115

psig (1-4°C at 7-8 bar) and a suction line temperature of 38-

44°F at 114-128 psig (3-7°C at 8-9 bar). In order to prevent

overcharging during this stage, refrigerant should be added in

steps. This will allow time for the system to settle and prevent

‘overshooting’ the ideal charge. Condenser pressures and

temperatures remain similar to those in a conventional forced

air system. It is recommended that the coil be charged on a

high load day at the compressor’s highest speed.

Charging

Most system start ups require only an adjustment to the

refrigerant level of the system. Should further refinement

be required, the TXV may be adjusted. A clockwise turn of

the superheat adjustment stem (the direction in which the

cap is screwed on) will result in a closing of the valve while a

counterclockwise turn (the direction in which the cap was

unscrewed) will result in opening of the valve. Always note

system conditions before adjusting the valve and allow 5 minutes

for the system to settle before making any further adjustments.

Never adjust the TXV more than one quarter turn at a time.

-7-

-7-

Important:

Failure to follow the proper

evacuating and charging procedures may

void warranty.

Module RBM

RBM Refrigerant Base Module Installation

Summary of Contents for RBM-100

Page 2: ......