Path contours – Polar coordinates

6.5

6

TNC 320 | User's Manual

HEIDENHAIN Conversational Programming | 3/2014

209

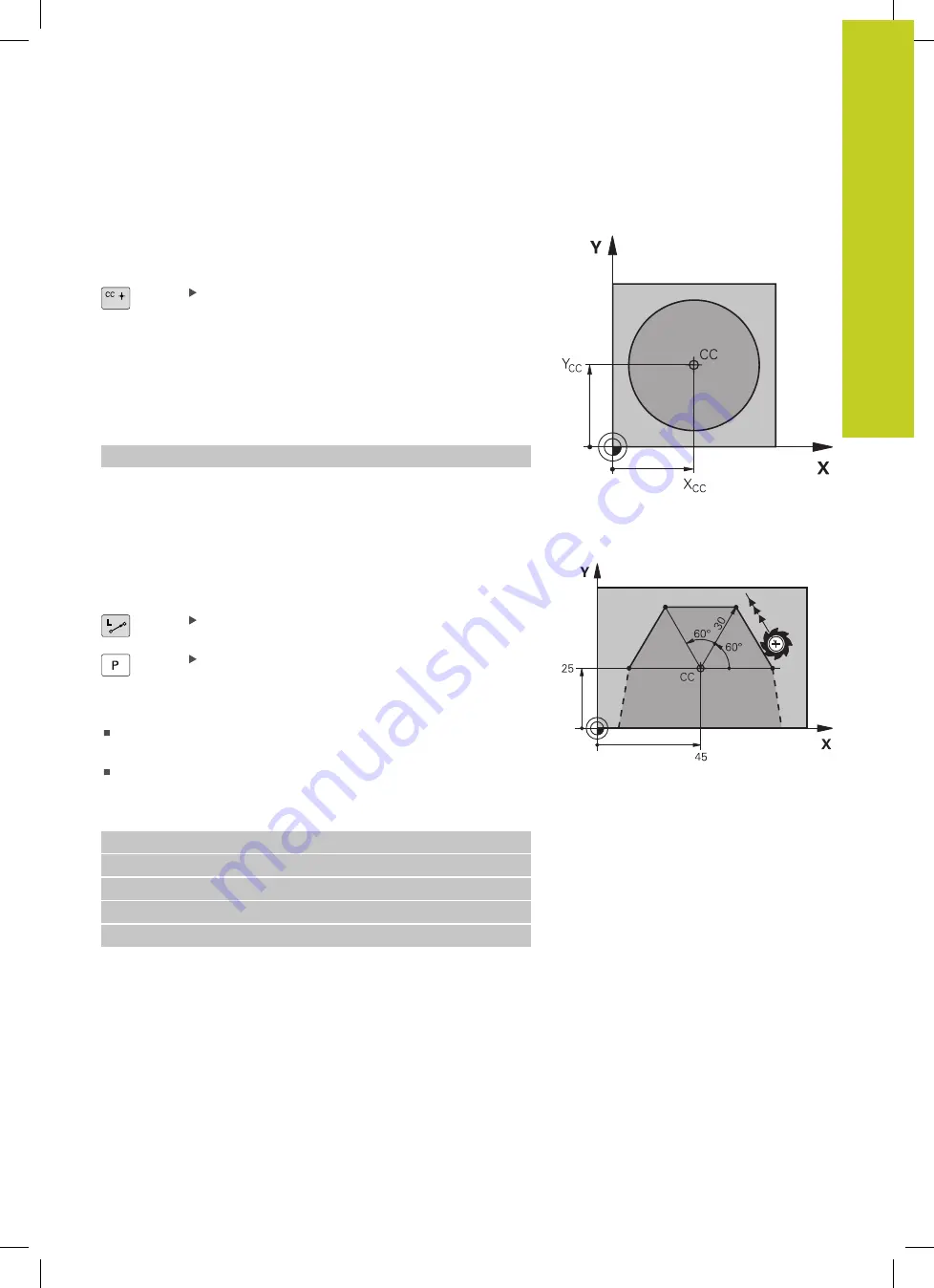

Zero point for polar coordinates: pole CC

You can define the pole CC anywhere in the part program before

blocks containing polar coordinates. Set the pole in the same way

as you would program the circle center.

Coordinates

: Enter Cartesian coordinates for the

pole or, if you want to use the last programmed

position, do not enter any coordinates. Before

programming polar coordinates, define the

pole. You can only define the pole in Cartesian

coordinates. The pole remains in effect until you

define a new pole.

Example NC blocks

12 CC X+45 Y+25

Straight line LP

The tool moves in a straight line from its current position to the

straight-line end point. The starting point is the end point of the

preceding block.

Polar coordinate radius PR

: Enter the distance

from the pole CC to the straight-line end point.

Polar coordinate angle PA

: Angular position of the

straight-line end point between –360° and +360°

The sign of

PA

depends on the angle reference axis:

If the angle from the angle reference axis to

PR

is

counterclockwise:

PA

>0

If the angle from the angle reference axis to

PR

is clockwise:

PA

<0

Example NC blocks

12 CC X+45 Y+25

13 LP PR+30 PA+0 RR F300 M3

14 LP PA+60

15 LP IPA+60

16 LP PA+180

Summary of Contents for TNC 320

Page 4: ...Controls of the TNC 4 TNC 320 User s Manual HEIDENHAIN Conversational Programming 3 2014 ...

Page 5: ...Fundamentals ...

Page 16: ...Contents 16 TNC 320 User s Manual HEIDENHAIN Conversational Programming 3 2014 ...

Page 43: ...1 First Steps with the TNC 320 ...

Page 63: ...2 Introduction ...

Page 81: ...3 Programming Fundamentals file management ...

Page 124: ......

Page 125: ...4 Programming Programming aids ...

Page 152: ......

Page 153: ...5 Programming Tools ...

Page 180: ......

Page 181: ...6 Programming Programming contours ...

Page 232: ......

Page 233: ...7 Programming Data transfer from DXF files or plain language contours ...

Page 251: ...8 Programming Subprograms and program section repeats ...

Page 267: ...9 Programming Q Parameters ...

Page 337: ...10 Programming Miscellaneous functions ...

Page 357: ...11 Programming Special functions ...

Page 379: ...12 Programming Multiple Axis Machining ...

Page 406: ......

Page 407: ...13 Manual operation and setup ...

Page 462: ......

Page 463: ...14 Positioning with Manual Data Input ...

Page 468: ......

Page 469: ...15 Test run and program run ...

Page 497: ...16 MOD functions ...

Page 525: ...17 Tables and overviews ...