P - 1

IMPORTANT

The following section contains important information regarding the safety and

operation of PTO drive equipment. As our spreaders are sold throughout the world

we install a standard length PTO shaft to accommodate multiple types and brands of

tractors. Therefore, modification (i.e. shortening) of the shaft may be required to

meet the specific needs of your tractor. Follow the guidelines set forth in this manual

to ensure proper and safe operation of your spreader.

HOW TO SHORTEN THE PTO DRIVE SHAFT

1)

Attach the implement to the draw bar. Align the implement with the tractor on

level ground - this will be the position at which the driveline is at its shortest

length. If the driveline will fit the tractor and implement at this point, without

bottoming out, no further action is necessary.

2)

If the driveline will not fit without bottoming out, separate the driveline

into two half shafts. Mount the tractor half on the PTO, and mount the

implement half on the power input connection (PIC).

3)

Hold the two halves side-by-side. Mark the outer shield tube where it overlaps

the end of the shield cone on the implement half shaft, plus 1/4".

4)

Disassemble the shields from the half shafts.

5)

Cut the outer shield tube at the mark made in (c). Using the cut piece as a

guide, cut an equal amount from the inner shield tube, the outer drive tube,

and the inner drive tube.

6)

Using a half round or rat tailed file, carefully deburr the cut end of the drive

tubes. Shake and/or wipe metal chips / filings from the drive tubes.

7)

Coat the inner drive tube with #2 grease along its entire length.

8)

Reassemble the shields onto each half shaft. Slide the inner half shaft into the

outer.

Summary of Contents for PT-6 FSS

Page 1: ...Model PT 6 FSS Fertilizer and Lime Spreader SERIAL __________________ WORK ORDER ___________...

Page 2: ......

Page 8: ......

Page 12: ......

Page 13: ...Fertilizer and Lime Spreader Safety...

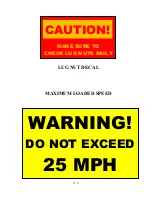

Page 17: ...S 4 PTO SAFETY DECAL...

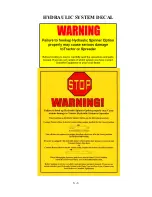

Page 19: ...S 6 HYDRAULIC SYSTEM DECAL...

Page 20: ...S 7 ROTATING CHAIN WARNING ROTATING SPINNERS WARNING...

Page 21: ...PTO Shaft Adjustment And Maintenance...

Page 24: ......

Page 25: ...Section 1 Basic Information...

Page 26: ...1 1 6PT FSS...

Page 27: ...1 2...

Page 29: ...Section 2 PTO Drive Spinners...

Page 33: ...2 4...

Page 36: ...2 7 Hydraulic Cylinder Engagement Assembly...

Page 38: ......

Page 39: ...PTF 71 2 RZ PTO Drive Spinner Gear Case Assembly and Parts List...

Page 43: ...Section 3 Full Press Wheel Drive Assembly...

Page 44: ...3 1...

Page 47: ...3 4...

Page 48: ...3 5...

Page 49: ...3 6 Hydraulic Cylinder Engagement Assembly...

Page 51: ...PTF 71 2 RZ FP Full Press Wheel Drive Spinner Gear Case Assembly and Parts List...

Page 55: ...Section 4 Press Wheel for Plug to Tractor Hydraulic Spinners...

Page 58: ...4 3...

Page 61: ...4 6 Hydraulic Cylinder Engagement Assembly...

Page 63: ...Section 5 Hydraulic Spinners...

Page 64: ...5 1...

Page 67: ...5 4...

Page 68: ...5 5...

Page 74: ......

Page 75: ...Section 6 Flow Divider Assembly...

Page 76: ......

Page 77: ...5 4...

Page 79: ...Section 7 Rigid Axle Assembly...

Page 80: ...7 1 6 Bolt 7 000 per Pair Hub Assembly J I H G A F E C B D L K...

Page 82: ...7 3 8 Bolt 12 000 per Pair Hub Assembly J I H G A F E C B D L K...

Page 85: ...Section 8 Basic Set Up Operation...

Page 88: ...8 3...

Page 90: ......

Page 91: ...Section 9 Maintenance Troubleshooting...

Page 97: ...Section 10 Spread Pattern...

Page 101: ...10 4 Data Recording...

Page 102: ...10 5 Data Recording Unacceptable Pattern Acceptable Pattern...

Page 104: ...10 7 Acceptable Pattern Using a 3 Pass Switchback Driving Method...

Page 106: ...10 9 Notes...